Case study

Pramac Ibérica: technological excellence with renewed energy

Story and pictures courtesy of I. González/Revista TOPE

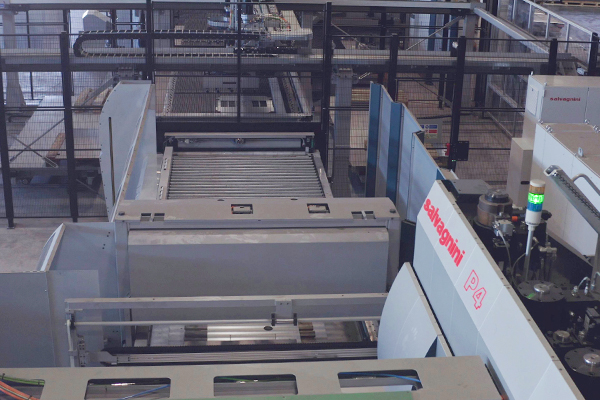

Pramac manufactures and markets electrical generators and maintenance systems in 180 countries through an extensive distribution network, employing more than 600 people in its 5 factories and 14 commercial branches worldwide. In the magnificent 22,000 m2 Pramac Ibérica facilities in the Murcia Parque Empresarial Polaris, the manufacturer of generators and tailored energy solutions relies on a Salvagnini S4 + P4 line.

Technological excellence with renewed energy

Highlights

- The project

In the words of the General Manager of Pramac Ibérica and the Regional Director in charge of the markets of Spain, Portugal, Lusophone Africa and LATAM countries, Andrés Granados Cabrera, there were there reasons why this investment was held to be necessary: "Firstly, we needed to increase the capacity of the punching section in the workshop. At the same time, we also needed to increase flexibility so as to ensure we had guarantees in the sheet metal processing for our latest developments. Lastly, it was time to replace our previous Salvagnini panel bender, purchased more than 15 years previous, but which was still perfectly functional." - Flexible and fast

The Chief Operating Officer of Pramac Ibérica, Francisco Javier Hernández García, tells us: "In the new punching machine, we process sheet metal more than 4 meters long, whereas in the new panel bender, we can reach a maximum bending length of 3,495mm, with minimal cycle times. At present, there are no other comparable solutions in terms of capacity and productivity available on the market. The ease with which this FMS produces finished parts is truly spectacular: punching, shearing and panel bending integrate into a process that can, moreover, work with a wide range of sheet metal formats and thicknesses".

Check out the case study

Hear what Pramac Ibérica executive team says about Salvagnini machinery.