Case study

Salva Industrial: quality partners

Story and pictures courtesy of I. González/Revista TOPE

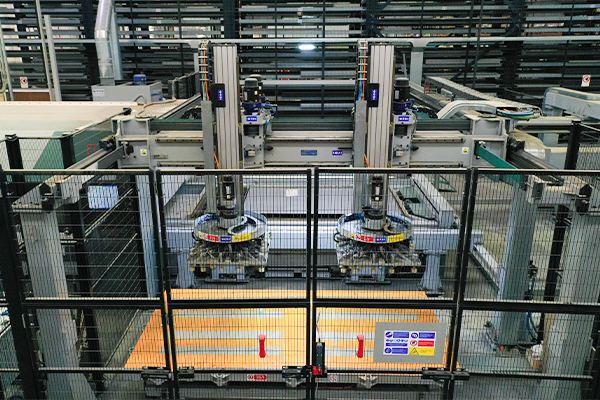

With more than 75 years behind it, Salva Industrial develops professional solutions for bakers and cake-makers looking for top quality equipment. And in its manufacturing process, the Gipuzkoa-based company leads by example: an MV automatic tray-store by Salvagnini is the cornerstone of a fully-automated factory with fully-integrated logistics, from the design of the equipment through to the delivery of the product to the customer.

Quality partners

Highlights

- Salva Industrial

Salva Industrial's manufacturing base boasts impressive installations that cover around 20,000 m2. The company is now an established international point of reference in the manufacture of top-of-the-range ovens for bakers and caterers: modular ovens, convection ovens, rotary ovens, cyclothermic ovens, electric deck ovens and annular tube ovens. And this just goes to prove the quality, reliability and hard-wearing design of this equipment: 80 percent of ovens sold by the company in the last 20 years, continue to work today. - Salvagnini solutions

Salva has spent more than 15 years getting maximum performance out of the Salvagnini MV automatic tray-store. This solution allows for the real-time coordination and transfer of all the sheet metal flows needed for each process (laser cutting, punching, shearing and panel bending), cutting costs and reducing wait time, while increasing the factory’s overall efficiency. Thanks to the Salvagnini software, the material to be processed flows automatically from cutting to bending in a fully integrated production process. "Although at first sight, its size makes it look like a less flexible system than traditional loading and unloading systems, this could not be further from the truth. We are firmly convinced that this is the best solution for what we need. It is perfect for us. The wide range of ovens we manufacture leads us to work with a great variety of metal sheet, which may need to be laser cut, punched, sheared or bent. This system allows us to access the sheet metal immediately and release it when necessary," says David Llordés, General Manager of Salva. "The productivity and flexibility of this system are shown day-in, day-out in the factory and accompany the entire production process. At present, it runs for 24 hours a day, 5 days a week, so reliability needs to be top class too."