Case study

Studio 54: a compact laser to increase productivity and process efficiency

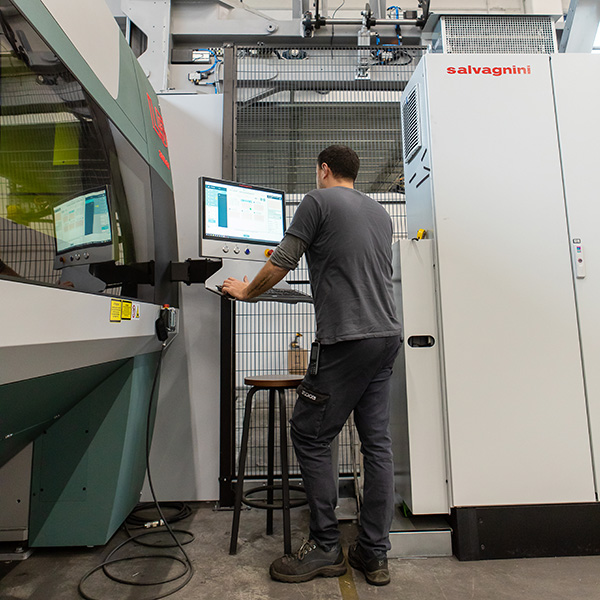

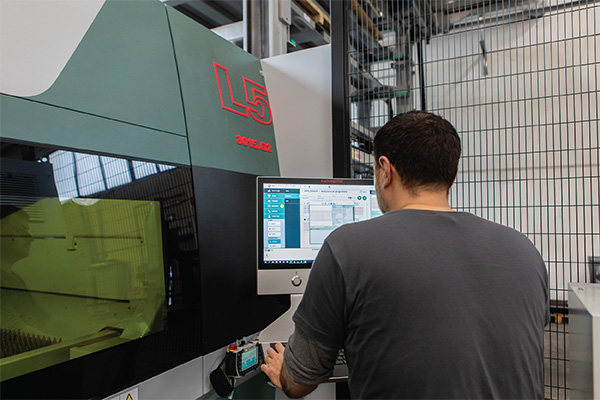

Studio 54 is a company from Padua, Italy, that has been supplying professional refrigeration equipment to the HO.RE.CA. and retail sector since 1994. We met the Chairman of the Board of Directors, Marco Bruseghin, to talk about the project which, in 2022, led to the installation of the second Salvagnini L5 laser, in its compact configuration with an LTWS store-tower for sheet metal loading/unloading.

A compact laser to increase productivity and process efficiency

Highlights

- Studio 54

Studio 54 is a company from San Giorgio in Bosco (PD) that has been supplying professional refrigeration equipment to the HO.RE.CA. and retail sector since 1994. In addition to its standard products – refrigerator cabinets, prep counters, blast chillers, refrigerated displays, bar equipment and hot display cases – Studio 54 also custom-builds products to respond to all its customers’ needs. - The scenario

The company’s machine inventory includes several Salvagnini systems, including two L5 high-dynamic fiber lasers, both equipped with automatic loading/unloading systems, a P4-2116 stand-alone panel bender and three B3 press brakes, one of which is equipped with an ATA device used to change and automatically adjust the length of the upper bending tools. - The project

In 2021, Studio 54 realized that to keep it up with this growth, it had to increase its production capacity: the laser, in particular, already worked between 18 and 20 hours a day, partially manned. With the support of the Salvagnini specialists, the company chose a new L5 fiber laser fed by an LTWS store-tower in a compact configuration for automatic sheet metal loading/unloading.