FSJ: FMS for independent and collaborative production

The Flexible Smart Job Shop (FSJ) is a combination of advanced technologies, software, artificial intelligence and vision (AI), robotic and automation solutions for dynamically facing the challenges of the modern market.

FSJ manufactures fast. Adapts faster.

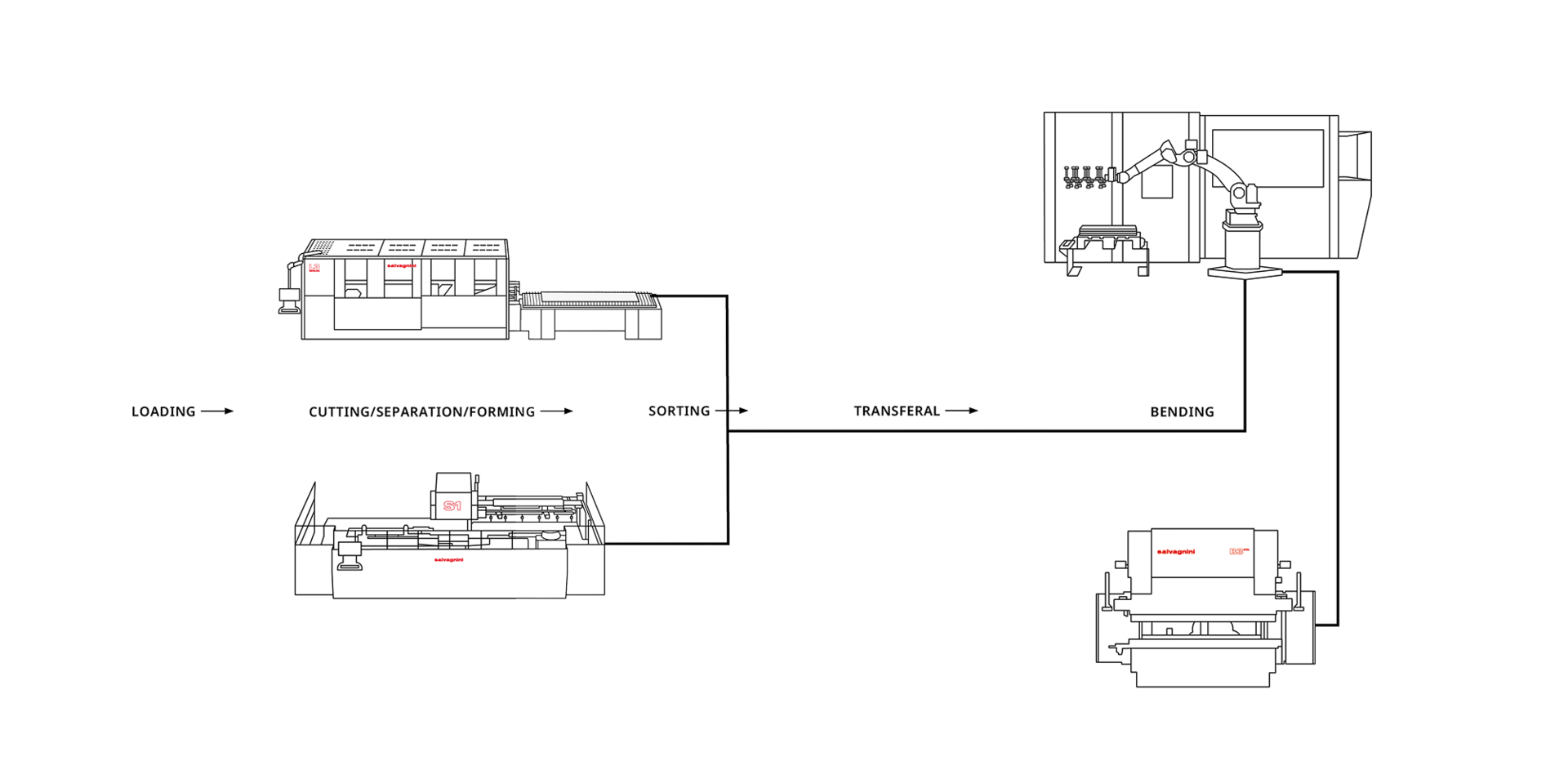

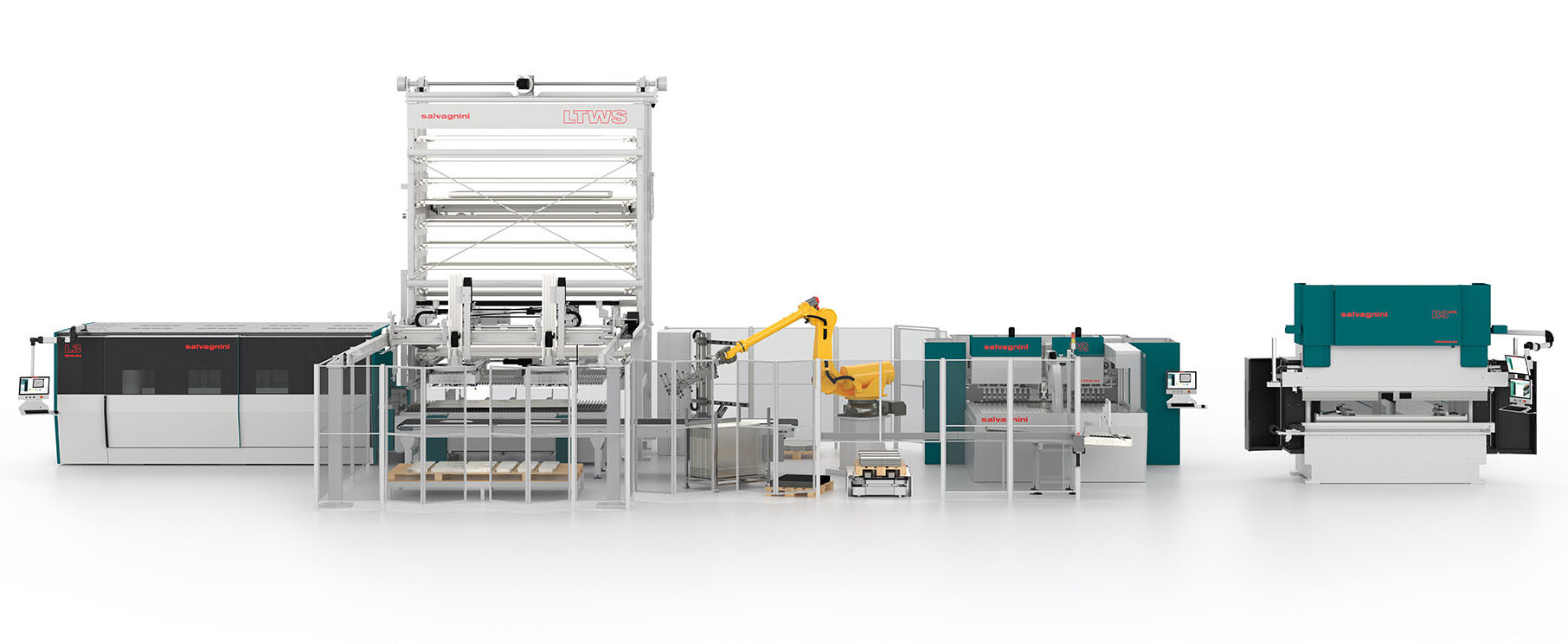

FSJ integrates advanced cutting and separation, bending and panel bending technologies, combining them with automatic and/or robotized devices and solutions for the loading and unloading, handling and intermediate transfer of materials. The result is a modular and scalable solution that optimizes production efficiency, reduces factory entropy and maximizes the performance of every single system.

Product overview

Salvagnini technologies permit the automatic production of different parts without operator intervention or machine downtime for retooling. The software makes it possible to easily and immediately interrupt the production sequence in urgent cases or for other needs. The machines also remain available for H2H processing.

The systems that make up the FSJ can operate individually or in a collaborative manner, adapting to diversified production needs, from the creation of small batches to the production of complex kits. The integration of intermediate stores and upstream and downstream workstations ensures an extraordinary level of flexibility, ideal for optimizing production flows and supporting just-in-time production, thereby reducing idle times and waste.

The integration of robotic systems or autonomous mobile robots (AMR) optimizes the management of the production flows, thereby eliminating bottlenecks and increasing operational efficiency.

The RVS artificial vision system simplifies the management of robotized assistance, accelerates the intermediate recognition and handling steps, maximizing the value of the finished part.

The FSJ is a true automatic and independent factory that requires relatively reduced spaces. It optimizes the transfers and methods for handling the parts and parallelizes activities with compact and performing devices.

FSJ combines evolved technologies for cutting, sorting, bending and panel bending, combining them with automatic and robotic solutions for the loading, unloading, handling and intermediate transfer of materials.

Cutting, separation, and forming solutions

Bending solutions

Independent machines

The laser cuts the sheet metal. MCU sorts the parts on the table (1) while the P-Robot picks up the parts from the loading station and stacks them as needed (2). The operator ends the bending on the press brake (3).

Convergent production

Production flow for kits. Once the cutting process is complete, MCU sorts the parts and puts them on the conveyor. P-Robot picks them up and produces them autonomously thanks to RVS. The production can be sent to a downstream operation (1) or stacked dynamically (2).

Today, operating steps in factories and workshops often take place in departments that are physically distant from each other, resulting in logistical and productive inefficiencies.

The innovative idea behind the Flexible Smart Job Shop is to compact the technologies, eliminating distances in the factory to permit adjacent processing and therefore reduce lead times and minimize superfluous movements, without compromising operational flexibility.

The FSJ comprises integrated systems and technologies that operate in an optimized and compact space. Even if they were designed to mainly operate in stand-alone mode, they can also operate in a continuous flow, thanks to automatic intermediate handling and artificial vision solutions.

The main advantage of this configuration is the reduction in factory entropy: while working with different technologies, production can proceed with certain, balanced times and through efficient work flows.

Various elements contribute toward the application versatility of the FSJ:

- advanced software programming

- intelligent sorting

- evolved bending technologies

- automatic intermediate handling

Salvagnini has developed and optimized all of these aspects through unique, modular and scalable solutions that are able to optimize factory space, logistics and store management, guaranteeing maximum efficiency, and productivity.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the line. LINKS allows real-time monitoring of the machine’s performance and independent analysis.