High performance and versatile fiber laser

Designed to improve ergonomics and simplicity of use and guarantee maximum precision and repeatability of processes, the L3.G4 eliminates activities with low added value and optimizes consumption, ensuring lower costs per piece.

Product overview

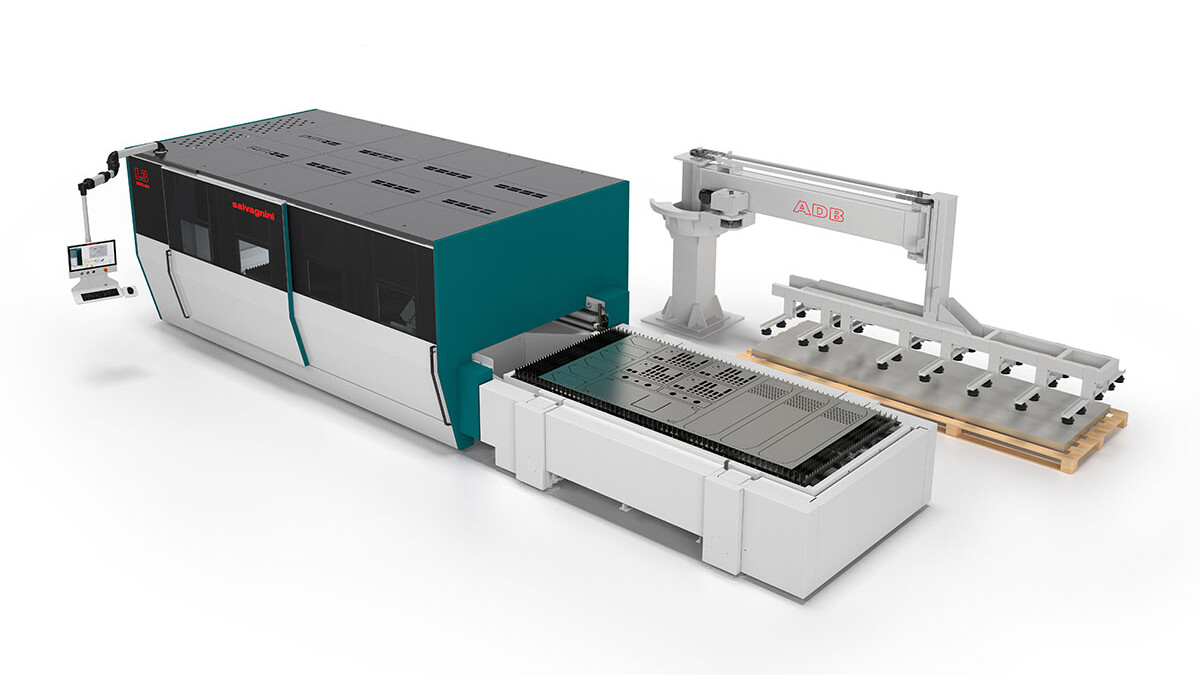

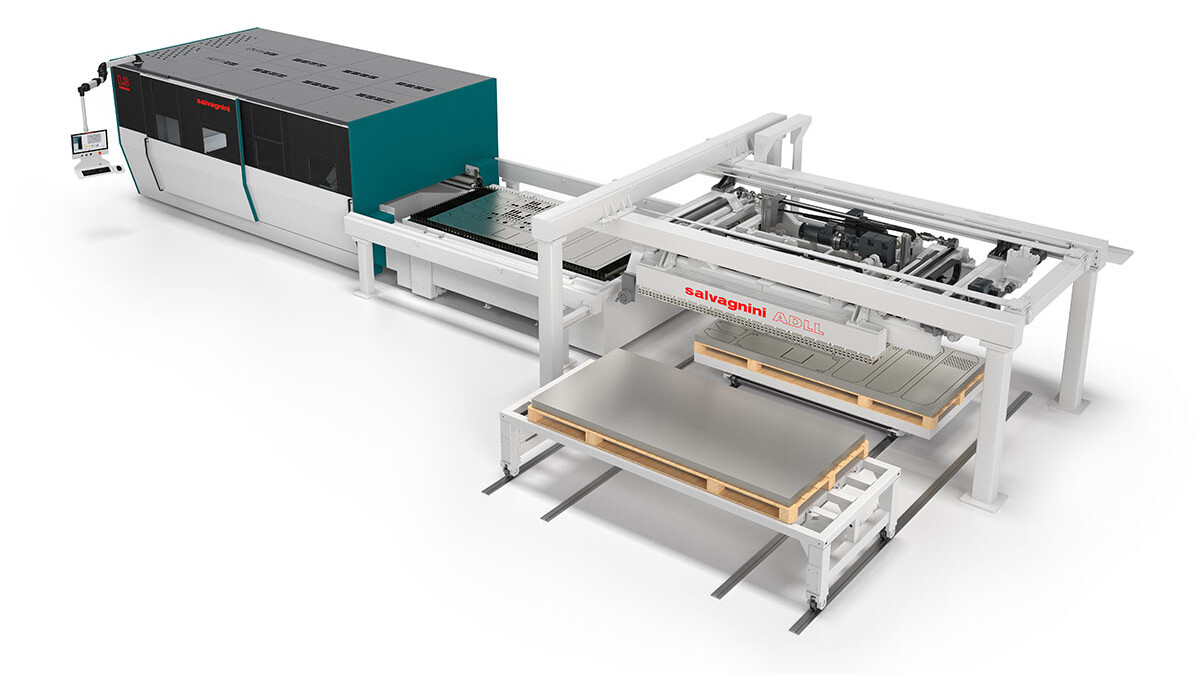

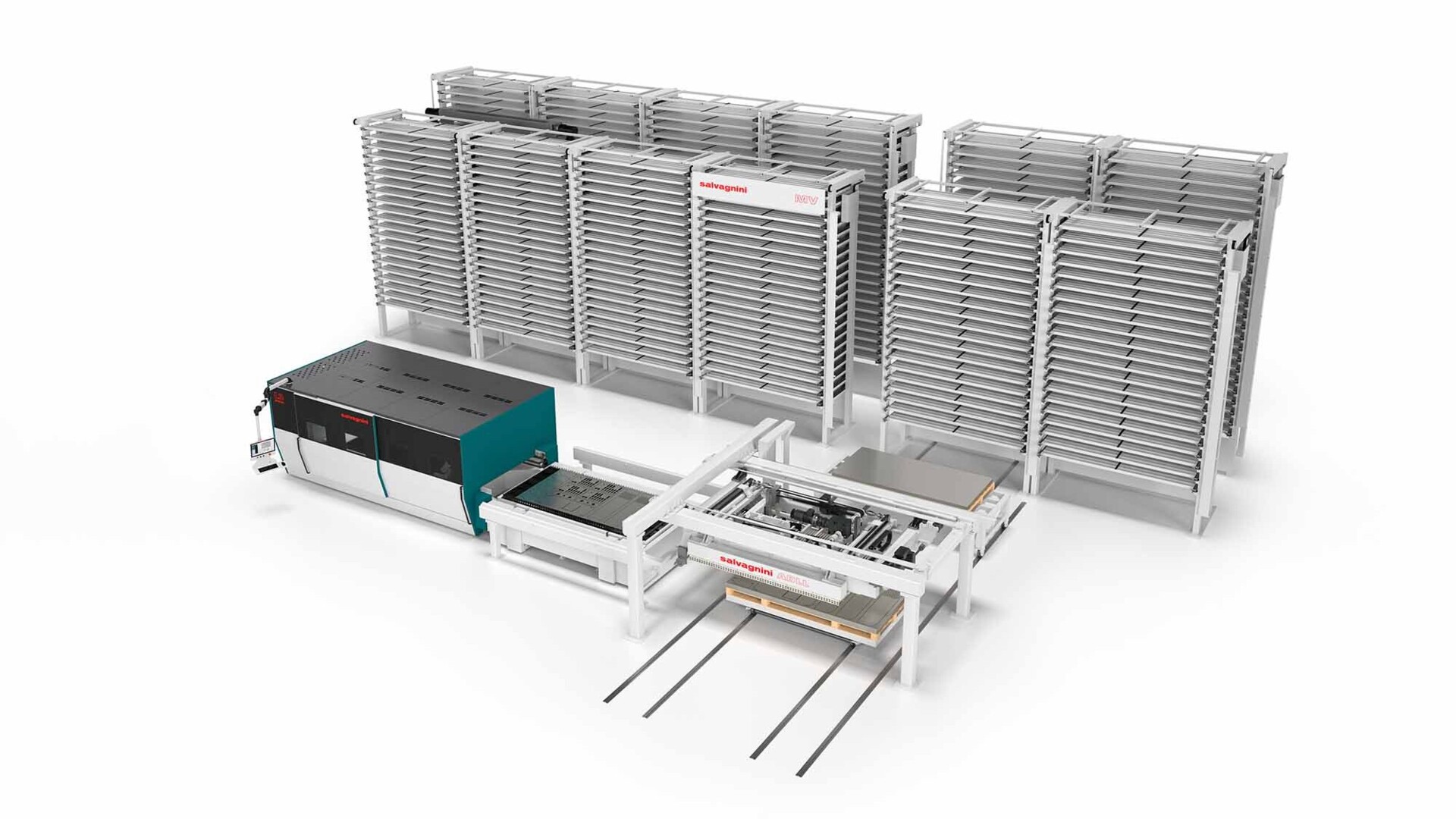

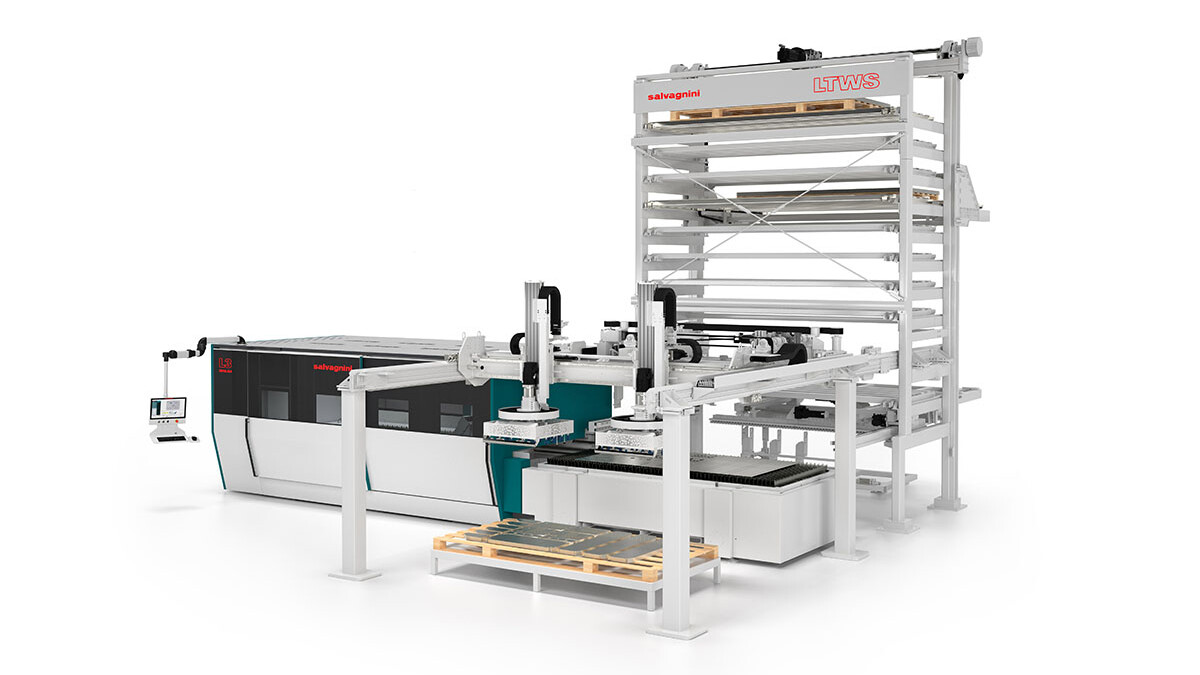

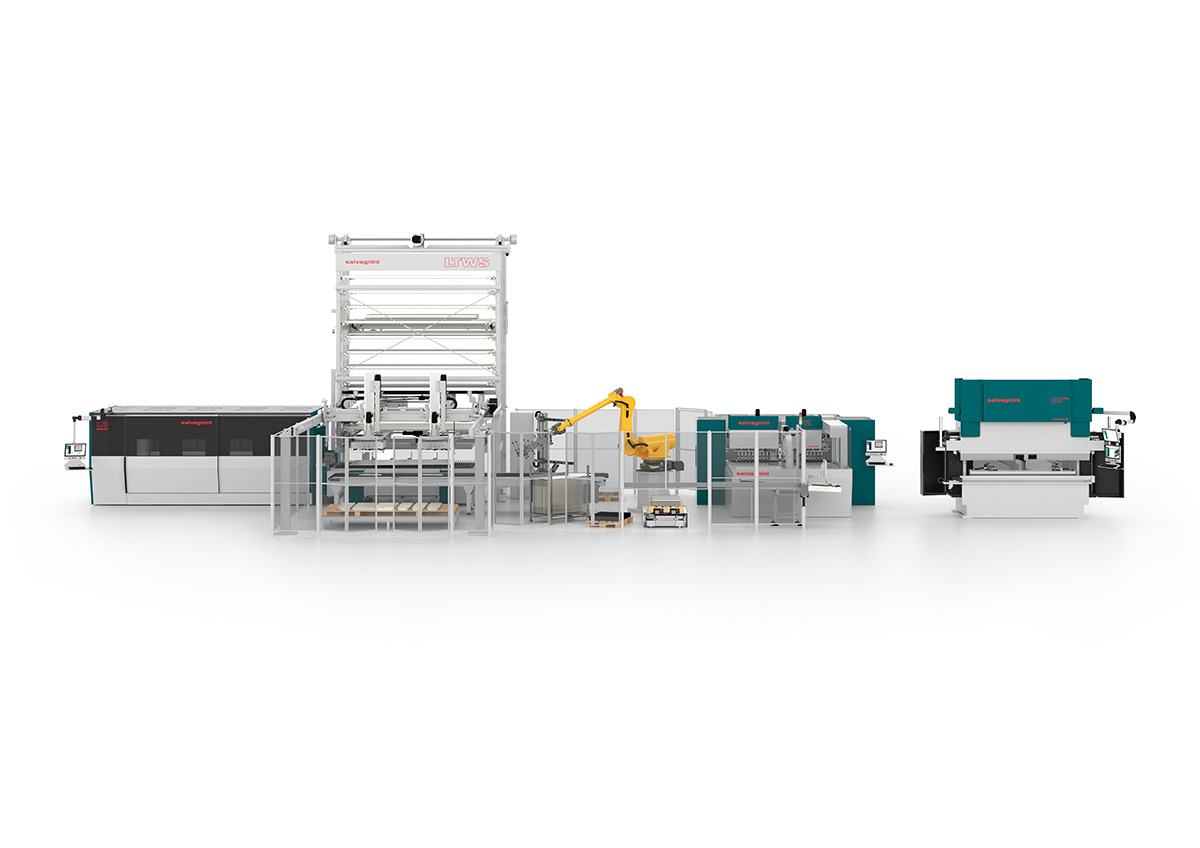

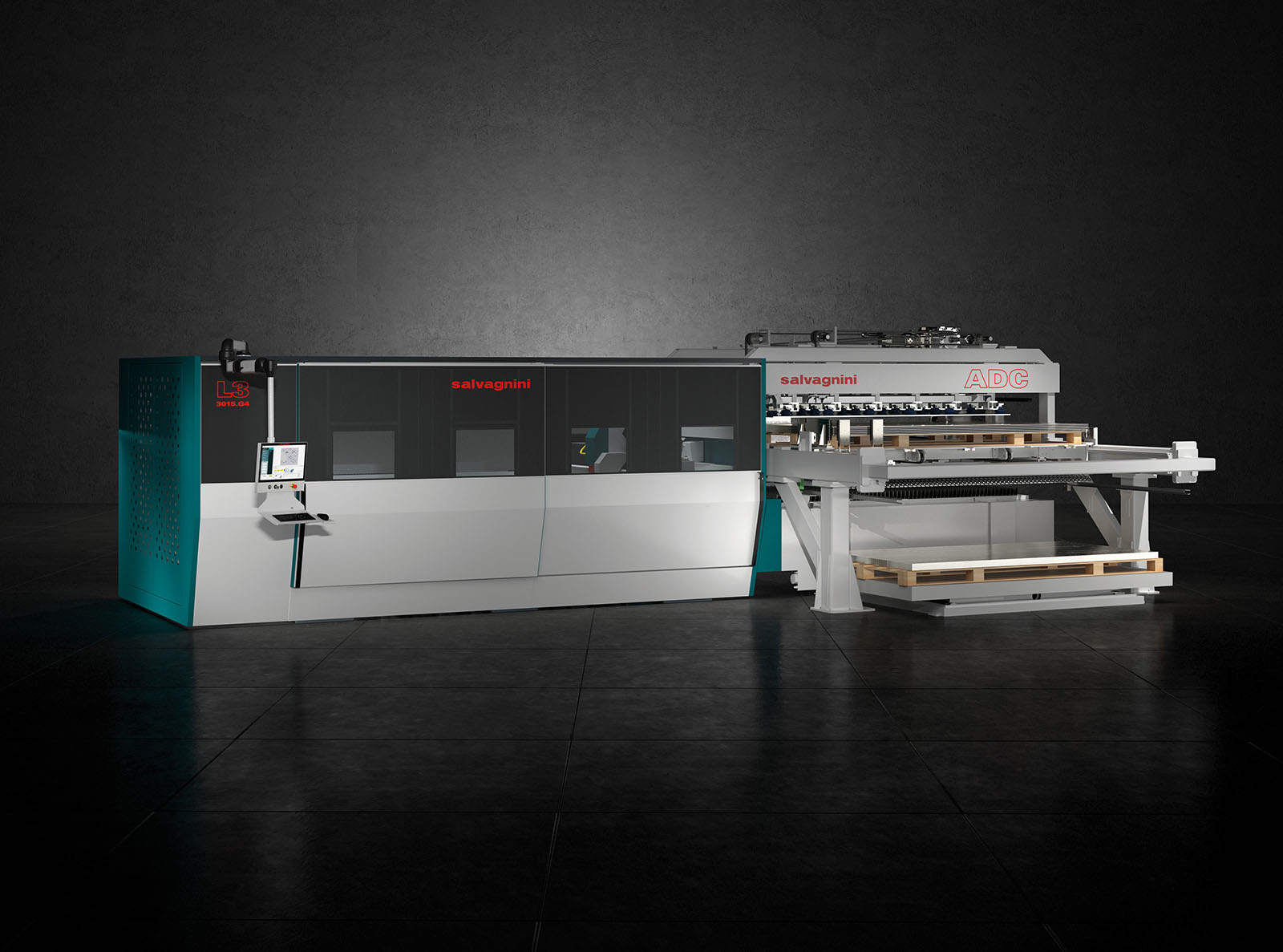

Storage and automatic loading/unloading/sorting devices increase the autonomy of the system, regaining efficiency both in individual processing steps and throughout the production process, eliminating bottlenecks and reducing the impact of labor costs.

Proprietary functions such as TRADJUST, the simple and intuitive multi-task interface, together with maximum accessibility, the worktable, artificial vision systems and part tracking and identification solutions, allow operators to effortlessly solve any problems they come across in their day-to-day work, making the L3.G4 agile and easy to use.

The wide range of solutions for process control and efficiency, evolved sensors, the rigidity of the structure, the easy to program and intuitive interface and software eliminate the low value operations, eliminate downtime and the risk of errors, improving precision and expanding the fields of application, increasing factory performance and keeping consumption reduced and operating costs competitive.

In the laser world, automation is playing an increasingly key role: on the one hand, cutting speeds risk turning loading and unloading into bottlenecks, and on the other hand, automation can help to reduce the impact of labor costs. The loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

Intelligent system, constant quality

Practically everything you ever wanted to know about the L3.G4 fiber laser, satisfactorily explained.

L3.G4 is Salvagnini solution for high-performance and versatile laser cutting, characterized by an innovative, highly accessible architecture that is unique in the market. Designed to improve ergonomics and simplicity of use and guarantee maximum precision and repeatability of processes, L3.G4 eliminates activities with low added value and optimizes consumption, ensuring lower costs per piece.

Today factories are required to face increasingly complex challenges, including regaining autonomy and optimizing operating efficiency. Laser cutting systems have become extremely fast and productive, but have uncovered new critical aspects, in particular during the loading, unloading, sorting and tracking steps. These operations are often transformed into real bottlenecks or generate errors that irrevocably undermine a factory’s potential.

- Automation: the wide range of automatic loading, unloading and sorting systems, units with efficient tracking solutions improve performance while minimizing errors and dependence on labor.

- HMI and office software: the simple and intuitive FACE human machine interface and STREAM software suite facilitate daily use for operations and prevent programming from becoming a production bottleneck.

- ERP/MRP integration: the OPS process software synchronizes perfectly with ERP/MRP enterprise systems, automating information distribution and making the production process smoother and error free.

Thanks to these solutions, Salvagnini is confirmed as a unique partner of reference, guaranteeing a reliable production process with a high level of performance.

Thanks to Salvagnini’s multi-level automation solutions, which are applied both for the individual production steps and for eliminating low added value activities and bottlenecks.

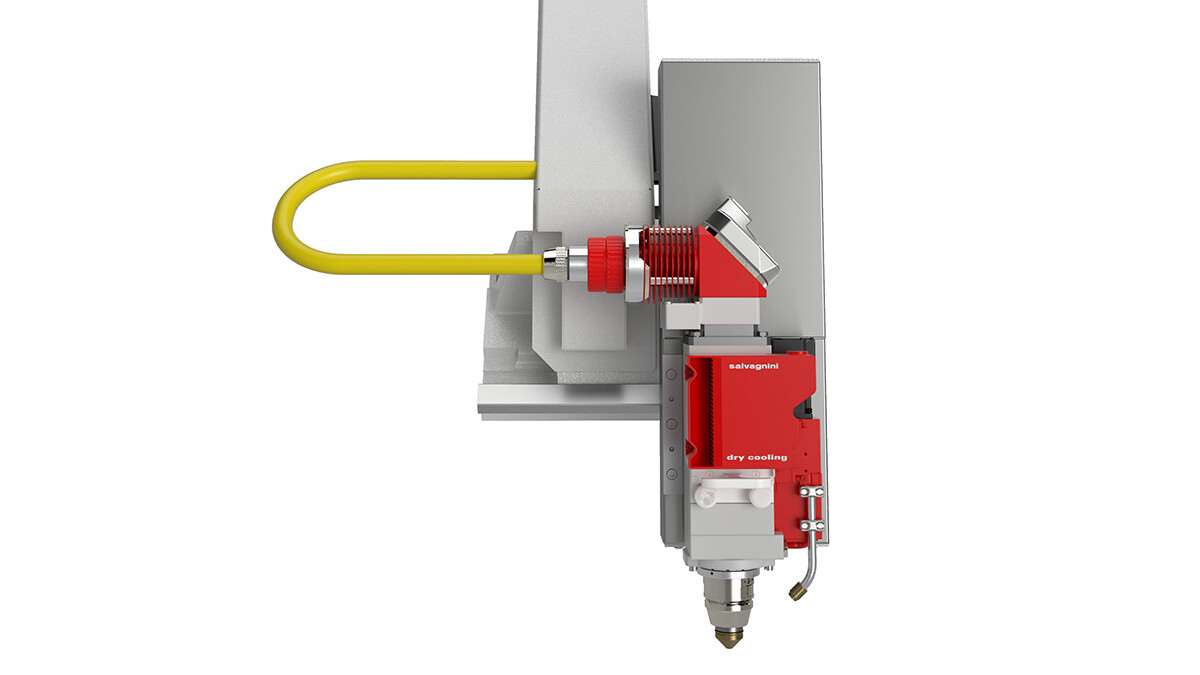

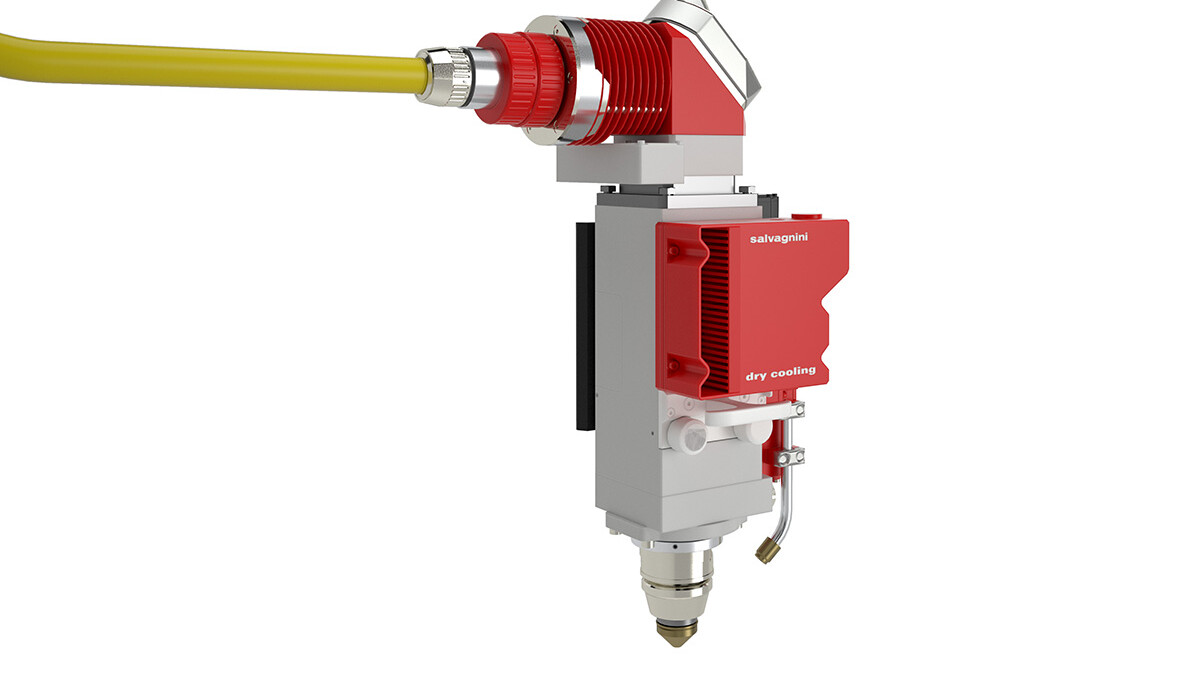

- The single optic cutting head machines all the workable thicknesses and materials, does not require any adjustment and speeds up production changeovers.

- The tradjust function, integrated into the proprietary control, ensures automatic parameter modulation in accordance with the trajectories, making the system easier to use.

- The artificial vision applications based on neural networks are simple solutions that increase system flexibility and extend their fields of application.

- The automatic loading/unloading and sorting devices reduce idle times for sourcing the sheet metal and the risk of error or damage to the material during stacking.

- The simple, user-friendly software solutions facilitate the production process and reduce errors and operator intervention times.

Production capacity corresponds to the sum of work and losses. The more automation reduces, if not completely eliminates redundant and low-added value activities upstream and downstream of the individual systems, with preparation, feeding and connection functions, the more profitable it is. In production contexts with low volumes and rapid production changes, connecting automatic loading/unloading devices and intuitive, easy-touse software, like NEXUS and STORE, is a winning strategy for recovering efficiency and achieving great results.

The data from LINKS, the Salvagnini IoT solution, shows that the efficiency of a stand-alone laser system generally does not exceed 60%. This parameter varies with configuration: systems with automation have average efficiency values that are much higher, reaching 80% for horizontal loading/unloading solutions and even 90% if we consider the LTWS store-tower.

Salvagnini provides a wide range of services to guarantee efficiency over time, assuring maximum reliability and productivity. The range of services includes multi-level training for programming, using and maintaining the installed systems and exploiting their potential to the full, maintenance contracts, which guarantee maximum efficiency and reliability of your equipment, but also includes advanced services including data-driven analysis and optimization of production flows using the most modern digital instruments.

The minimum level of automation for the L3.G4 laser is the CPE device, the ultra-rapid electrical pallet changer. The raw material always passes above the material that has already been cut, preventing any scrap from previous machining being deposited on the sheet metal.

The productivity of a laser system is influenced by exterior factors, i.e. everything the system cannot

control, such as batch size, frequency of production changes and mix of materials/thicknesses; and by technological factors, such as source power, level of automation and digitalization.

The field of application, with its specific mix of materials, thicknesses and production strategies, is the key factor in the choice of technology: versatile, as in the case of the L3.G4, or with high dynamics, like the L5.

Increasingly small batch sizes need rapid automation for rapid or masked-time production changes. The Salvagnini automation range offers modular and compact systems for managing increased output, as well as systems that are open to downstream processes to be integrated into the factory’s production flow.

The range of thicknesses and the cutting performance depend on the power of the source: Salvagnini offers high-performance electronic sources including 6kW high-power density and 8kW high-power density and high-efficiency.

The adoption of evolved digital technologies makes it possible to implement and manage complex, integrated, highly automated high-performance systems, and can help develop simple solutions that require no structural changes to the production layout, making the world of smart manufacturing much more accessible.

Efficiency and productivity are achieved by eliminating downtime and optimizing every step of the process. These objectives can now be reached thanks to the integration of the most advanced digital technologies, such as software, IoT and AI. These solutions support the operator, assure realtime monitoring, facilitate interaction with the system and improve process visualization. Furthermore, they optimize operating activities, collecting and analyzing data received from the sensors, machinery and control systems. These technologies make it possible to define priorities, plan machining operations and interact with the external environment, thereby guaranteeing maximum process efficiency.

- Artificial vision applications increase the flexibility of the system and broaden its fields of application.

- The STREAMLASER programming software improves material efficiency and reduces costs.

- The SAFE GRID function automatically optimizes part positioning with respect to the grilles.

- The NEXUS software automatically generates the sorting programs. In addition to the traditional operating method that requires defining sorting strategies after creating the nesting program, NEXUS makes it possible to define the sorting strategies before creating the nesting program.

- The OPS process software receives the production list from the factory ERP/MRP in real time and supports the programming activities, defining priorities, rules and algorithms.

Increasing the productivity of a laser means guaranteeing efficiency throughout the whole process. The Salvagnini formula blends the power of the source with intelligent sensors and solutions integrated into the L3.G4 laser, automation upstream and downstream of the cutting process, and digitalization. The result? Higher performance, and an optimized production process.

Salvagnini has always worked to produce solutions with low environmental impacts, guaranteeing maximum operator safety, ergonomic use and resource optimization.

The L3.G4 is provided with high-efficiency energy sources, some of which also exceed 50% efficiency.

The patented AVC technology makes it possible to limit the consumption of compressed air by the automations because vacuum is generated only when necessary.

The ACUT option enables cutting sheets up to 20 mm thick with compressed air, with productivity similar to that of cutting with nitrogen but at significantly reduced costs.

The compact, turnkey APM2 device that can be connected to ACUT connects directly to the pneumatic system and ensures the pressure values required for the cutting process.

The Impacts software monitors consumption to proactively optimize it.

The adaptive technologies, proprietary algorithms, closed-chain controls and technological solutions adopted in the lasers make it possible to reduce scrap effectively, making best use of materials and reducing scrap, with high-efficiency power density unique to the market.

Every Salvagnini system is designed to:

- last a long time: it can be modified, updated or extended over the years, adapting to new strategies or new production needs;

- recyclable at end-of-life. Each system consists above all of steel mechanical parts and metallic perimeter guards, water painted without organic solvents or coloring agents containing heavy metals.

Whatever technology is chosen, Salvagnini guarantees:

- maximum operator safety, certified by the strictest regulations;

- maximum use of the system based on specific solutions for each field of application;

- simple use and proprietary system management and programming software optimized for each specific technology.

L3.G4 with a highly-accessible original gantry architecture guarantees maximum accessibility to the working range.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the laser system. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Technical data

| Model | L3-30.G4 | |

| XY working range (mm) | 3048 x 1524 | |

| Z axis stroke (mm) | 160 | |

| Maximum XY speed (m/min) | 170 | |

| Precision1 | ||

| Position accuracy Pa (mm) | 0.05 | |

| Average position range Ps (mm) | 0.03 | |

| Fiber sources | 2000W | 3000W | 4000W | 6000W | 8000WE5 | 8000W |

| Cutting capacity (maximum thickness in mm)2 | ||||||

| Steel | 15 | 20 | 20 | 25 | 25 | 25 |

| Stainless steel | 10 | 12 | 15 | 20 | 25 | 25 |

| Aluminum | 8 | 10 | 15 | 20 | 25 | 25 |

| Copper | 5 | 8 | 8 | 8 | 10 | 10 |

| Brass | 5 | 6 | 8 | 8 | 10 | 10 |

| Minimum thickness (mm) | 0.5 | |||||

| Consumption (in kW) | ||||||

| Maximum absorbed power (in kW)3 | 16 | 18 | 21 | 28 | 28 | 34 |

| Average absorbed power (in kW)4 | 11 | 12 | 13 | 16 | 16 | 20 |

1 Measurement calculated according to VDI3441 on maximum axis lengths.

2 Cutting quality on limit thicknesses may depend on geometries required, material quality and system operating conditions. At limit values, burrs may be present on the lower edge of the cut. These values are for the Salvagnini reference materials.

3 Maximum absorbed power calculated on the standard system configuration (machine, source, chiller, fume extractor), in 3 cutting cycles on mild steel from 0.8 to 6 mm.

4 Average absorbed power calculated on the standard system configuration (machine, source, chiller, fume extractor), in 3 cutting cycles on mild steel from 0.8 to 6 mm.

5 High efficiency version.