Case study

Knauf: a panel bender to manage small and customized batches

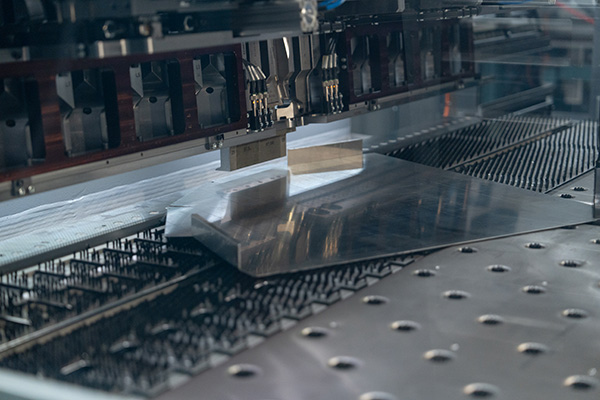

Knauf Ceiling Solutions supplies ceiling panels in three different densities in order to guarantee high levels of absorption and attenuation or a good balance between the two, to meet every need in all types of environments. The group's production site is located in Rankweil, and its plant has several Salvagnini systems including an S4+P4 line, an S4 stand-alone punching-shearing machine, two B3 press brakes and, from 2024 a P2-2120 panel bender.

A panel bender to manage small and customized batches

Highlights

- Knauf

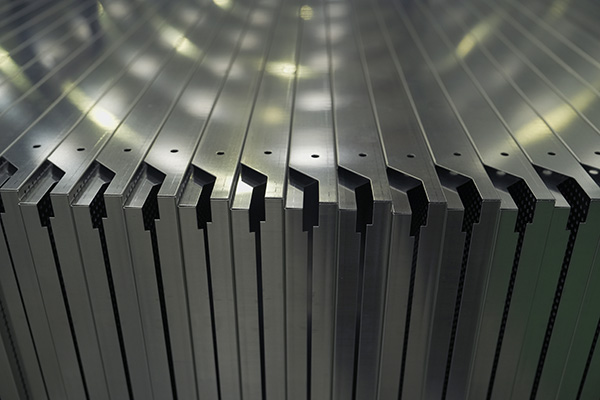

Among Knauf's strengths is the production of customized ceilings, a service, quality and consultancy-oriented mindset, as well as a know-how of excellence developed through the merge of three world-renowned ceiling manufacturers: Hoval, based in Austria founded in 1974, GEMA, in Switzerland, and finally the joining of the group Knauf Ceiling Solutions in 2019. Production at the Austrian plant, which employs 70 people, is wide and varied: economy batches but also single batches, large panels, and highly customized small batch production. - The context

The partnership with Salvagnini began over 20 years ago, when the first line consisting of an S4 punching-shearing center and a P4 panel bender was installed, the Group's trademark. The S4+P4 line, still active today, is mainly dedicated to the production of large panels. The S4 punching-shearing center in stand-alone configuration, installed in 2014, on the other hand, is dedicated to cutting and punching panels to be processed with the two Salvagnini B3 press brakes. - The project

"We decided to purchase the P2 panel bender to further enhance our production flow by automating even the bending steps of the smallest and most complex parts," explains Florian Kainz, Plant Manager. Tool set-up times were a key factor in the choice of technology: "In the past, we used to calculate between 5 and 10 minutes between one production process to the next, for tool changes. Today, with the introduction of a P2 panel bender, those precious minutes are invested entirely in the production stages, with extreme benefits in terms of time and production efficiency." - The outcome

"Together with Salvagnini, we were able to develop a solution that offered us great advantages, especially for triangular parts", describes once again Kainz. The customization of the blankholder and the P-tool gave Knauf the possibility to easily handle, and with high precision and repeatability, even the most complex parts, which are usually difficult to process on the panel bender, but which are fundamental in order to guarantee the special features for which the company is recognized at international level. "In Salvagnini, we found a partner who strongly supports us in flexible automation and with whom we can meet our customers' wishes".

Check out the case study

Hear what Florian Kainz, Plant Manager at the Rankweil site, says about this project.