White paper

One line for different production strategies

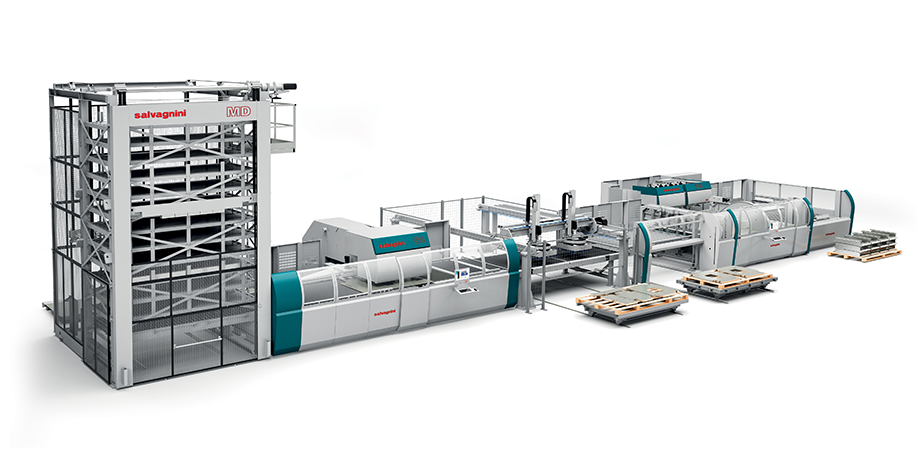

The S4+P4 line, introduced by Salvagnini in 1979, ensures continuous production of kits and batch one, minimizing cycle times, semi-finished parts and intermediate handling. It can be configured according to the space available, the degree of automation and autonomy needed, the context and production strategies, or the productivity required. All in all, the S4+P4 line is the ideal solution for producing, with maximum flexibility, what is needed, when it is needed – just in time.

Highlights

- Why

Passing from a traditional layout, with independent workstations, to a fully integrated configuration with a Salvagnini S4+P4 line, increases flexibility and maximizes production capacity. - Configurability

The configuration may be short, tight, without unloading devices between the S4 and P4, and may be progressively enhanced with intermediate devices for loading, unloading, stacking and turning over parts. - Production strategies

The S4+P4 can run line production, off-line production, but also work using stack mode, pack mode, dynamic buffering.

One line for different production strategies

The S4+P4 line punches, shears and bends sheet metal totally automatically, without any intermediate handling. Among other benefits, the line allows to produce on demand and just in time, to increase capacity and velocity, to reduce lead time, to process different materials without retooling, to optimize manpower activities.