What is a panel bender?

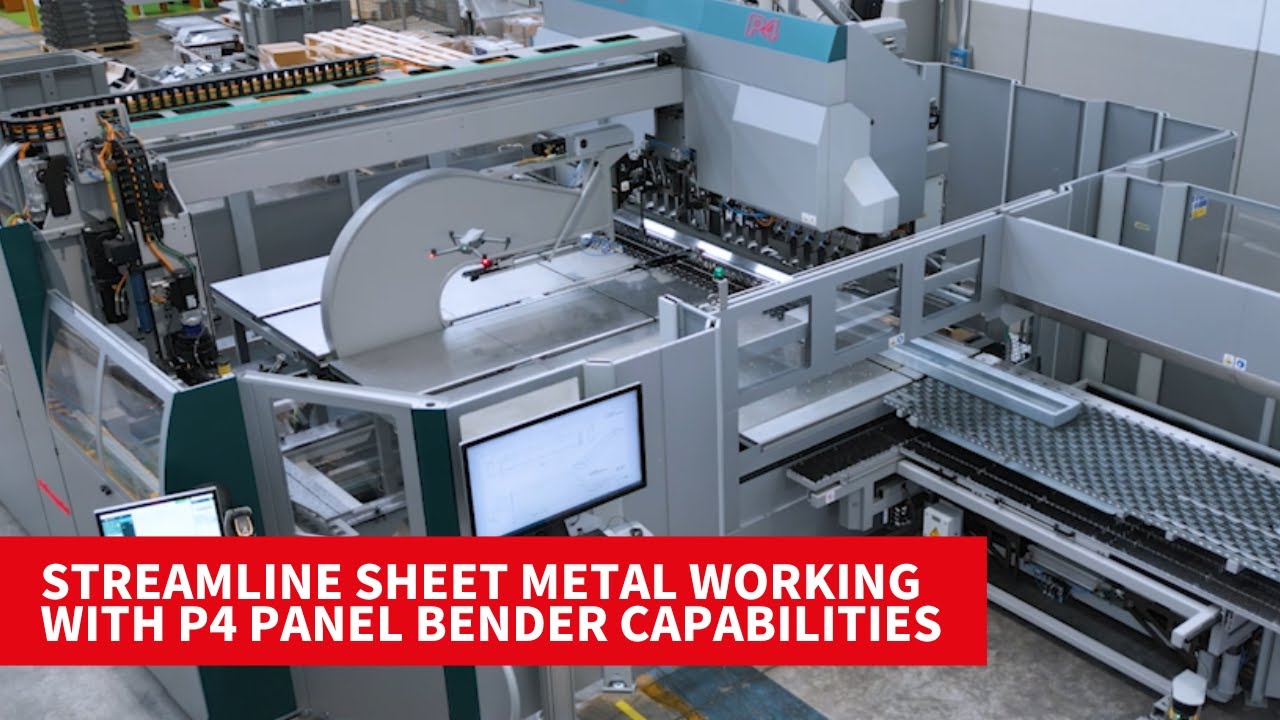

The Salvagnini panel bender is an advanced sheet metal bending machine that streamlines the entire bending process. Designed for productivity, efficiency, and flexibility, it adapts to different batch sizes and material thicknesses, ensuring high-quality, repeatable results with minimal manual intervention.

Since inventing the panel bender in 1977, we set the global standard in automated bending solutions. With over 4.000 of installations worldwide, our technology continues to evolve, making bending effortless for manufacturers processing sheet metal up to 3.2 mm thick.

With the Salvagnini panel benders, you get:

Easier bending

Simplifies operations, reduces strenuous tasks, and creates a more welcoming work environment, making staffing easier.

High productivity

Bend at speeds of up to 17 bends per minute, ensuring peak efficiency and continuous production while lowering labor costs without overtime or additional shifts.

Smart programming

The intuitive STREAM software and user-friendly FACE interface enable fast, precise programming, reducing errors and optimizing production time.

Extreme performance

Higher output, consistent quality, 100% repeatability with every bend.

Optimized material usage

Top precision sheet metal bending with minimal waste.

Predictable costs

Automated bending streamlines production management, enhancing cost control with greater safety and reliability.

Seamless production changes

Adapt instantly to different materials and items, and to batch-one and high-mix production.

Effortless automation

Automatic tool adjustments and handling, reducing manual intervention.

Compact footprint

High performance even in compact layouts, ideal for space-constrained companies.

More information?

Do you have specific questions or need further details? We’re here to help.

Contact us to learn more about how Salvagnini can support your production needs.

Operating mode: simple, quick and lean

Bending on each side of the sheet is achieved thanks to the controlled interpolated movements of the blades.

Flexible automation

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 3.2 mm, during the cycle and without machine down times or manual re-tooling.

Proprietary bending formula

Developed over the years, the bending formula defines the force and manages the movements of the universal tools, analyzing different parameters in real time, including deflections, temperature and thickness, guaranteeing the precision, repeatability and quality of the finished product.

Automatic manipulator: fast and accurate

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.

P-Robot

P-Robot is the application combining a Salvagnini panel bender with a robot to produce kits, batches, and single parts autonomously.

Trusted by manufacturers: hear their experience

Melcher & Co. | Austria

Melcher & Co's investment in the Salvagnini P4 panel bender has significantly improved efficiency. The company increased production capacity, reduced cycle time, and achieved an 80% reduction in energy consumption. Additionally, the automation and precision of the P4 have minimized material waste and enhanced overall process reliability, leading to greater flexibility and cost savings.

FBT Elettronica | Italy

FBT Elettronica enhanced its production process with the introduction of the P2 panel bender. This technology improved operational efficiency by reducing production times and increasing flexibility. It also helped streamline workflows, minimizing dependence on external suppliers and ensuring quicker, high-quality production. The P2 played a key role in meeting the company’s growing demands.

Ricana Concept | Sweden

By investing in automation, Ricana Concept boosted its production capacity, reduced bottlenecks, and improved prototype turnaround times. Learn how the integration of a robot tuned their P2 panel bender into a P-Robot, eliminating production constraints and enhancing both product quality and employee ergonomics.

Krosno Metal | Poland

Krosno Metal benefitted from the introduction of the Salvagnini P1 panel bender by significantly reducing production costs per unit, improving efficiency, and streamlining operations. This innovation enabled them to maintain product quality while enhancing production speed and reducing overtime.

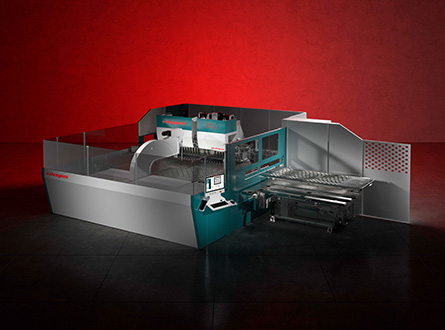

Our product range

We offer a versatile range of automated panel bending solutions to meet different production needs. Whether you're looking for a compact, flexible machine or a fully automated high-volume system, our panel benders are designed to enhance productivity, efficiency, and flexibility.

Explore the best panel bender for your production needs and take automated bending to the next level.

Auf nur 8m2 Stellfläche und mit einem maximalen Verbrauch von 3kWh bietet die P1 alle typischen Eigenschaften der Salvagnini-Biegezentren, die für die Kombination von Produktivität, Flexibilität und patentierter Kinematik konstruiert ist.

Mehr erfahren

Die PX kombiniert von jeher die Produktivität von automatischen Biegezyklen mit der Flexibilität der universellen Biegewerkzeuge. Für Leistungen ohne Kompromisse.

Mehr erfahren

Die P2 besticht mit hochtechnologischen Inhalten, geringem Energieverbrauch und kompaktem Design, ohne dabei die für die Salvagnini-Biegezentren typische Produktivität und Flexibilität zu vernachlässigen.

Mehr erfahren

Die P4 beeindruckt mit ihrem Konfigurationspotential und ihren Leistungen: Produktiv und flexibel, kann sie sowohl unabhängig als auch in einer flexiblen Zelle arbeiten oder in eine automatisierte Fabrik integriert werden.

Mehr erfahrenTechnical data

| Model | P1 | PX | P2 | P4 |

| Maximum length of incoming sheet (mm) | 1575 | 2495 | Range | Range |

| Maximum width of incoming sheet (mm) | 1000 | 1600 | Range | 1524 |

| Maximum diagonal that can be rotated (mm) | 1600 | 2500 | Range | Range |

| Maximum bending force (kN) | 90 | 330 | Range | Range |

| Maximum clamping force (kN) | 310 | 530 | Range | Range |

| Maximum bending length (mm) | 1250 | 2180 | Range | Range |

| Maximum bending height (mm) | 127 | 203 | Range | Range |

| Minimum thickness (mm) | 0.4 | 0.5 | 0.4 | 0.5 |

| Maximum thickness and bending angle steel, UTS 410 N/mm2 (mm) | Max 1.60 (±90°) | Max 2.5 (±90°) | Max 3.2 (±90°) | Max 3.2 (±90°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 (mm) | Max 1.30 (±90°) | Max 2.1 (±90°) | Max 2.5 (±90°) | Max 2.5 (±90°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 (mm) | Max 1.60 (±120°) | Max 3.5 (±90°) | Max 3.5 (±120°) | Max 4.0 (±120°) |

Values refer to a standard machine. Salvagnini reserves the right to modify this data without warning.

Full technical specifications are available on each panel bender's page.

More information?

Do you have specific questions or need further details? We’re here to help.

Contact us to learn more about how Salvagnini can support your production needs.