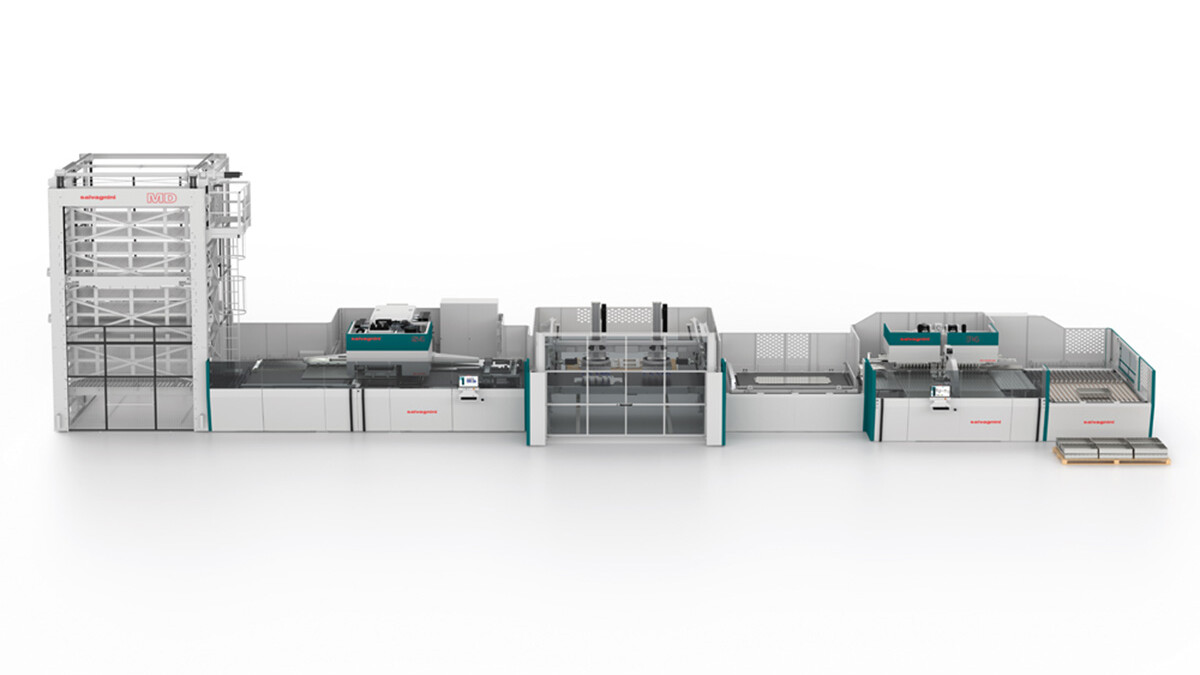

FMS Flexible Manufacturing Systems

Simply the line. Since 1979, it is the most efficient flexible manufacturing system on the market for sheet metal processing.

Learn moreFlexible automation

Salvagnini’s flexible production systems turn packs of sheet metal into a wide variety of products without operator intervention.

By optimizing individual production steps, they eliminate WIP and ensure traceability, minimizing activities with low added value and maximizing the efficiency of the entire process.

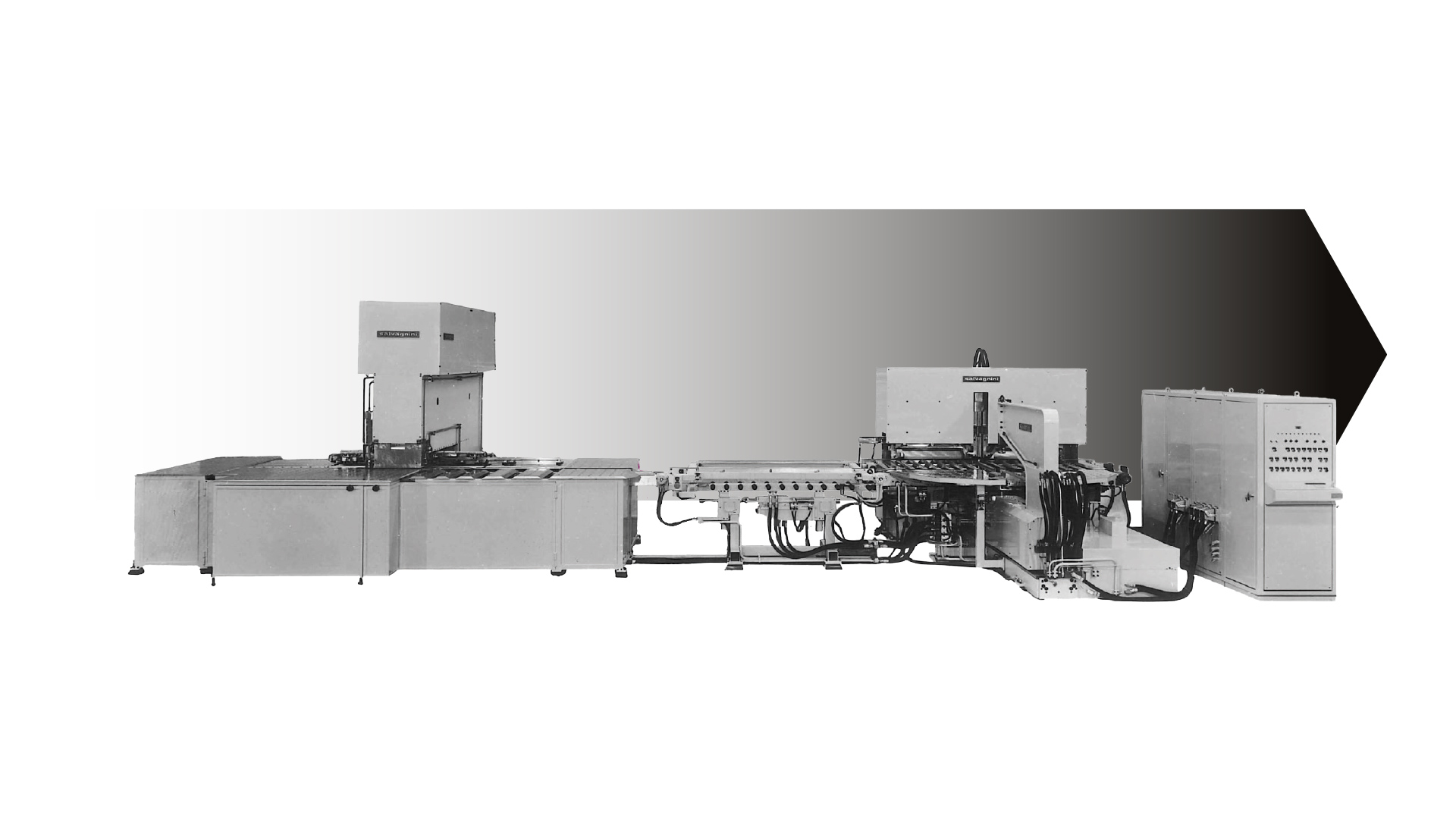

Engineering the future, every day

The world’s first flexible production system for sheet metal processing, a S4+P4 line, combines a S4 punching machine and a P4 panel bender, was presented by Salvagnini at the Hanover exhibition in 1979.

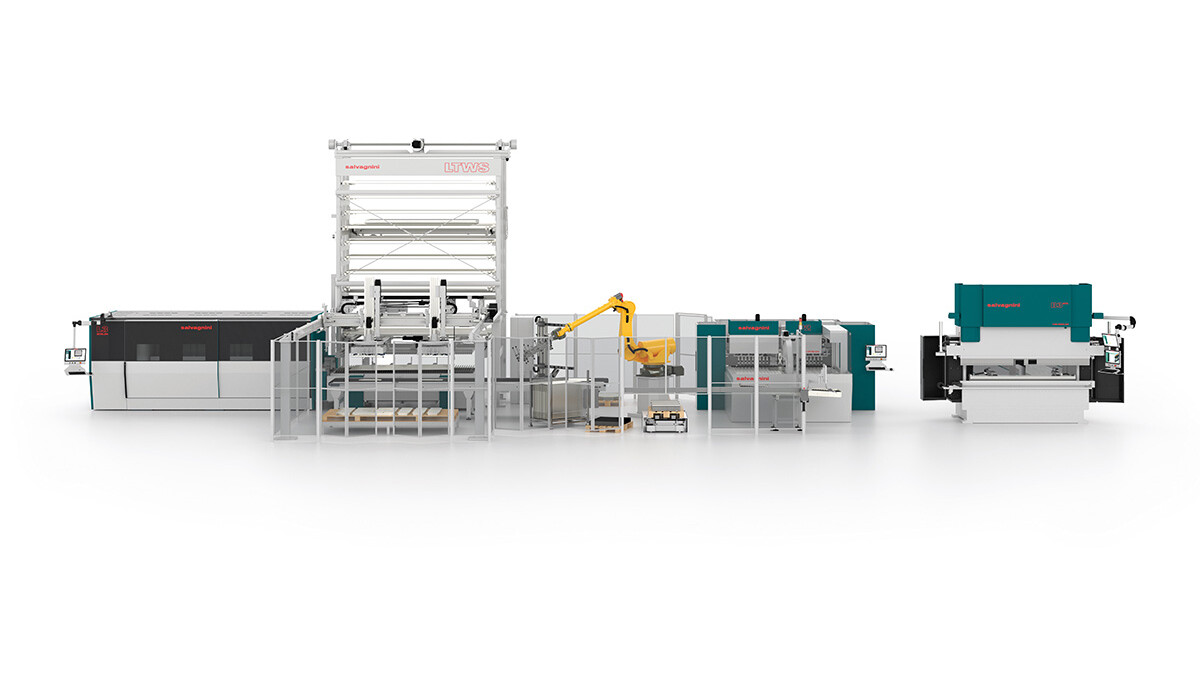

The drive of the 4.0 paradigm, the evolution of digital technologies and the growth of AI models have made it possible to evolve the concepts of the cell, factory and line giving new outlook and identity to the world of FMS.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the FMS. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Do you have any questions?