Case study

Pompetravaini: all the advantages of an integrated process

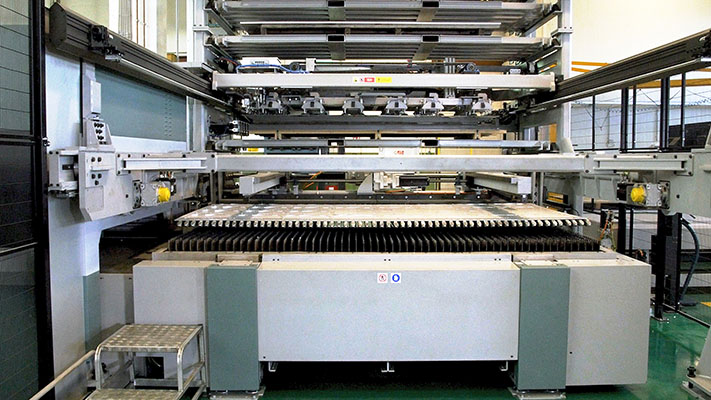

Carlo Travaini founded Costruzioni Meccaniche Carlo Travaini in 1929, manufacturing pumps and turbines on a subcontractor basis. Today, almost one hundred years on, Pompetravaini is one of the world’s top manufacturers of liquid-ring vacuum pumps and centrifugal pumps, exporting its products to over 80 countries. We met Federico Travaini, Vice-Chairman and the fourth generation of the Travaini family to work in the company, and Stefano Garofalo, Production Manager, to find out about one of the company’s latest investments: a Salvagnini L5 laser with LTWS store-tower.

All the advantages of an integrated process

Highlights

- Pompetravaini

With a turnover of around €30 million, 250 employees and operating facilities in the USA, Canada, France, Germany, the Netherlands, India, Turkey and Poland, today Pompetravaini is one of the benchmark brands on the global market for engineered vacuum systems and pumps, and for centrifugal and multi-stage pumps. - The context

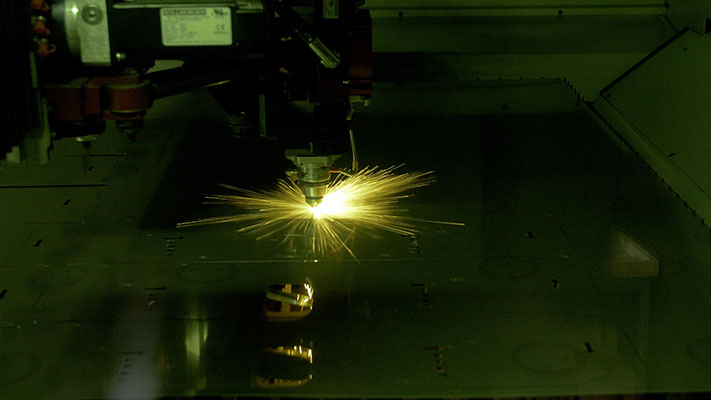

In 2013, when Pompetravaini installed a CO2 laser, they had the chance to see the full potential of this technology, and they were able to shorten the production chain. In recent years, however, some of the system's limits began to emerge: in addition to extremely long CO2 laser cycle times, there was no pallet changer, and this drastically reduced laser availability. - The project

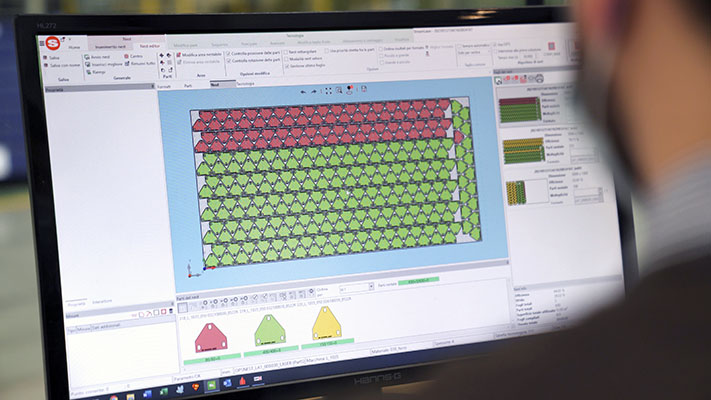

“That was when we met Salvagnini,” says Stefano Garofalo, Pompetravaini Production Manager. “After an in-depth study, we decided to invest in a new, highly automated laser system, which also allowed us to exploit all the benefits of production process digitalization.” - A cutting-edge laser

“The L5's availability and productivity have further reduced the sub-contracting chain, reducing procurement times and costs and improving product control," says Federico Travaini, Vice-Chairman and the fourth generation of the Travaini family to work in the company. "And this has also helped us to continue redesigning our products. Today, we use the laser to make the bases from metal sheets rather than from metal sections. At the same time, the laser guarantees the necessary precision for the parts in the next robotic welding phase. Today we produce a base in 5 minutes, and in 5 minutes we have to be able to provide the robot with the 11 or 12 sheet metal components it is made from: we are more reactive, and we have reduced the cost of the product.”

Check out the case study

Hear what Pompetravaini executive team says about the Salvagnini L5 laser.