Insight

Salvagnini's Innovations in the Sheet Metal Industry

In the ever-evolving world of manufacturing and production, standing out requires a blend of innovation, efficiency, and a commitment to quality. Few companies exemplify these values quite like Salvagnini America, a beacon of technological advancement in the sheet metal fabrication industry. When you think of sheet metal fabrication, it's hard not to think of Salvagnini. Let's dive deep and explore some of the pioneering innovations that our remarkable company has introduced to the market.

Flexible Systems for Greater Productivity

One of the defining features of Salvagnini is its commitment to flexible automation. Traditionally, sheet metal fabrication required extensive manual labor and separate machines for each step of the process. Salvagnini's introduction of the Panel Bender, for example, represented a paradigm shift in the way industries approached bending operations. By utilizing adaptive tooling and intelligent algorithms, these machines can automatically adapt to different panel designs, eliminating the need for manual tool changes and delivering exceptional speed and precision.

The P4: Revolutionizing Bending

When it comes to bending, Salvagnini's P4 machine stands out as a marvel of innovation. This piece of machinery, designed to save time, space, and energy, has revolutionized the bending process. Its automatic setup, direct from coil processing, and ability to handle multiple bends in quick succession make it an asset for any fabricator. The P4 automatic panel bender is not just a machine; it's a statement of how efficiency and innovation can come together.

Enhanced Punching Capabilities

The sheet metal punching process has also seen significant advancements, thanks to Salvagnini. Our punching machines boast high speed, flexibility, and impeccable accuracy. This ensures not only faster production times but also superior product quality. Coupled with advanced software solutions, Salvagnini's punching systems offer unprecedented levels of customization and adaptability.

Sustainable Manufacturing

In today's world, sustainability is not just a buzzword; it's a necessity. Salvagnini is well aware of this, integrating energy-saving features and eco-friendly technologies in our machines. Our commitment to reducing environmental impact, without compromising on efficiency or quality, is genuinely commendable, and something we are proud of, globally.

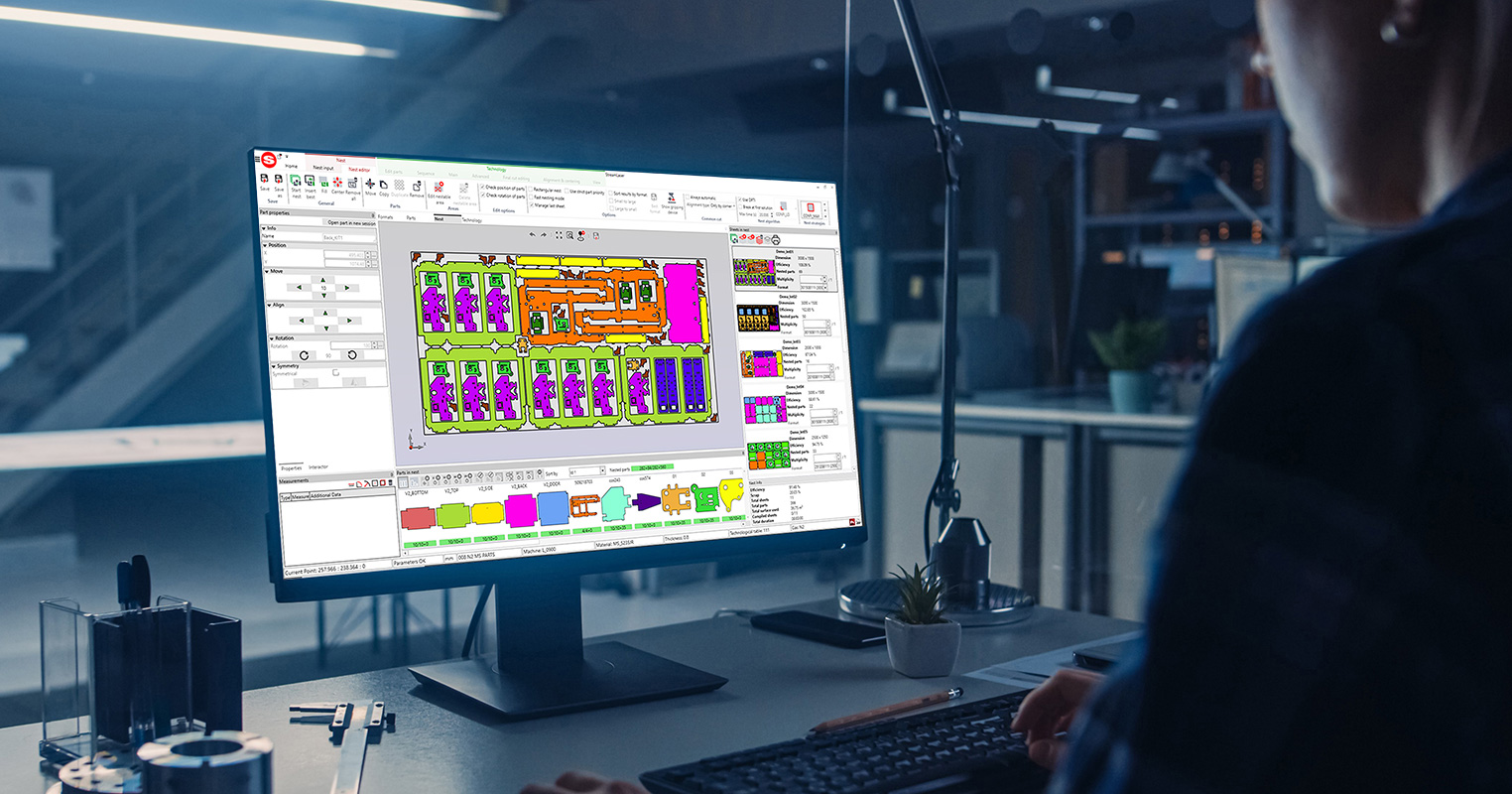

Integrated Software Solutions

Behind every Salvagnini machine is a sophisticated software system. Our dedication to developing advanced software ensures that all machines can be easily integrated into various manufacturing environments. This software allows for real-time monitoring, predictive maintenance, and seamless data integration, making it easier for operators to achieve optimal results.

Customer-Centric Approach

While technological advancements are essential, what truly sets Salvagnini apart is our unwavering commitment to our customers. We don’t just provide machines; we offer solutions. By actively engaging with customers, understanding their unique challenges, and customizing our products accordingly, Salvagnini ensures that we always remain a step ahead in meeting industry needs.

Salvagnini America's footprint in the sheet metal fabrication industry is undeniable. Our relentless pursuit of innovation, combined with a deep understanding of market trends and needs, has positioned us as leaders in the field. For our industry partners, this means embracing efficiency, quality, and a vision for the future. As we continue our journey, there's no doubt that we will remain at the forefront of sheet metal fabrication, driving the industry to new heights.

If you're keen on being part of the future of sheet metal fabrication, Salvagnini is the name to include in your manufacturing shop or digital job shop. Talk to our sales group to see how you can get started, today!

One line for different production strategies

The S4+P4 line punches, shears and bends sheet metal totally automatically, without any intermediate handling. Among other benefits, the line allows to produce on demand and just in time, to increase capacity and velocity, to reduce lead time, to process different materials without retooling, to optimize manpower activities.