The management and recovery of sheet metal leftovers – those residues of previous operations that nobody wants to waste, and are commonly reused to create samples, complete urgent jobs in single batches of parts of different sizes, or replace any scrap from the manufacturing processes downstream of cutting – is a common worry for companies equipped with a laser system. We know from experience that every workshop organizes and solves the first two steps of recovery, i.e. the logistics, storage and cataloging of leftovers, in the method that best suits the company's production strategy and the materials available: from simple text files listing the parts available to automatic software solutions for inventorying leftovers, and from storing the leftovers on sheet metal packs to stacking on shelves and on to more sophisticated warehousing solutions for more costly materials such as stainless steel. But storage and cataloging affect above all the times and effectiveness of the recovery activities and the search among the leftovers, which is the third step in the process. Finally, the last step in the recovery process is measuring the leftovers: the dimensions are required because the programmer, who is generally not in the workshop but in the office, has to refer to the formats available in order to generate the programs. As we can see, the leftover recovery process has many steps, and many activities which have a time-related cost. And the time devoted to managing urgencies, or producing single or small batches, has a greater weight and cost than those of the daily programming of production activities.

With a view to simplifying the process and making it more efficient, Salvagnini has introduced the SVS (Sheet/Scrap Vision System) option for its laser cutting systems. The SVS is an artificial vision system that enables sheet metal leftovers to be reused, producing a dxf which serves as a starting sheet for nesting new parts to be cut directly on board the machine. The option is available in two versions: the SVS1, which has a single camera focusing on the leftover and a working range of 1600x1500mm, and the SVS2, which uses two cameras and has a much larger working range of 3000x1500mm.

How does the SVS work?

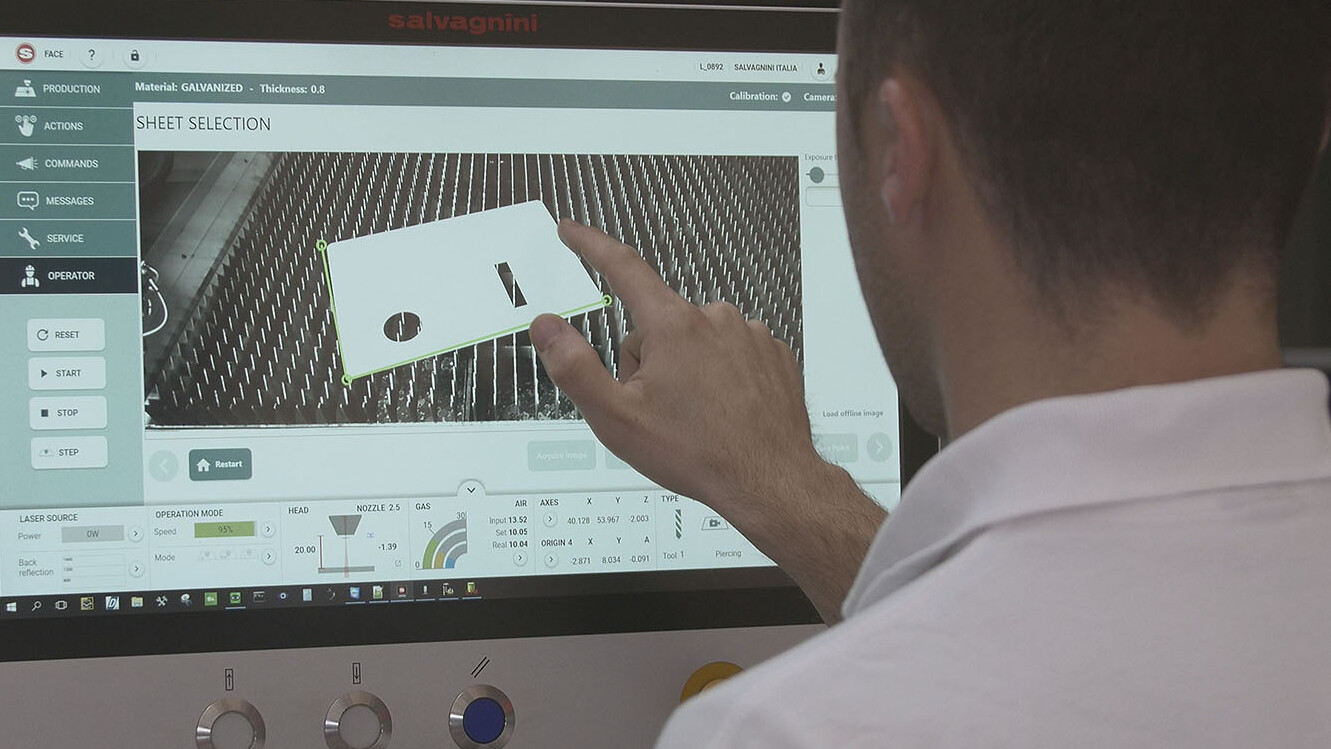

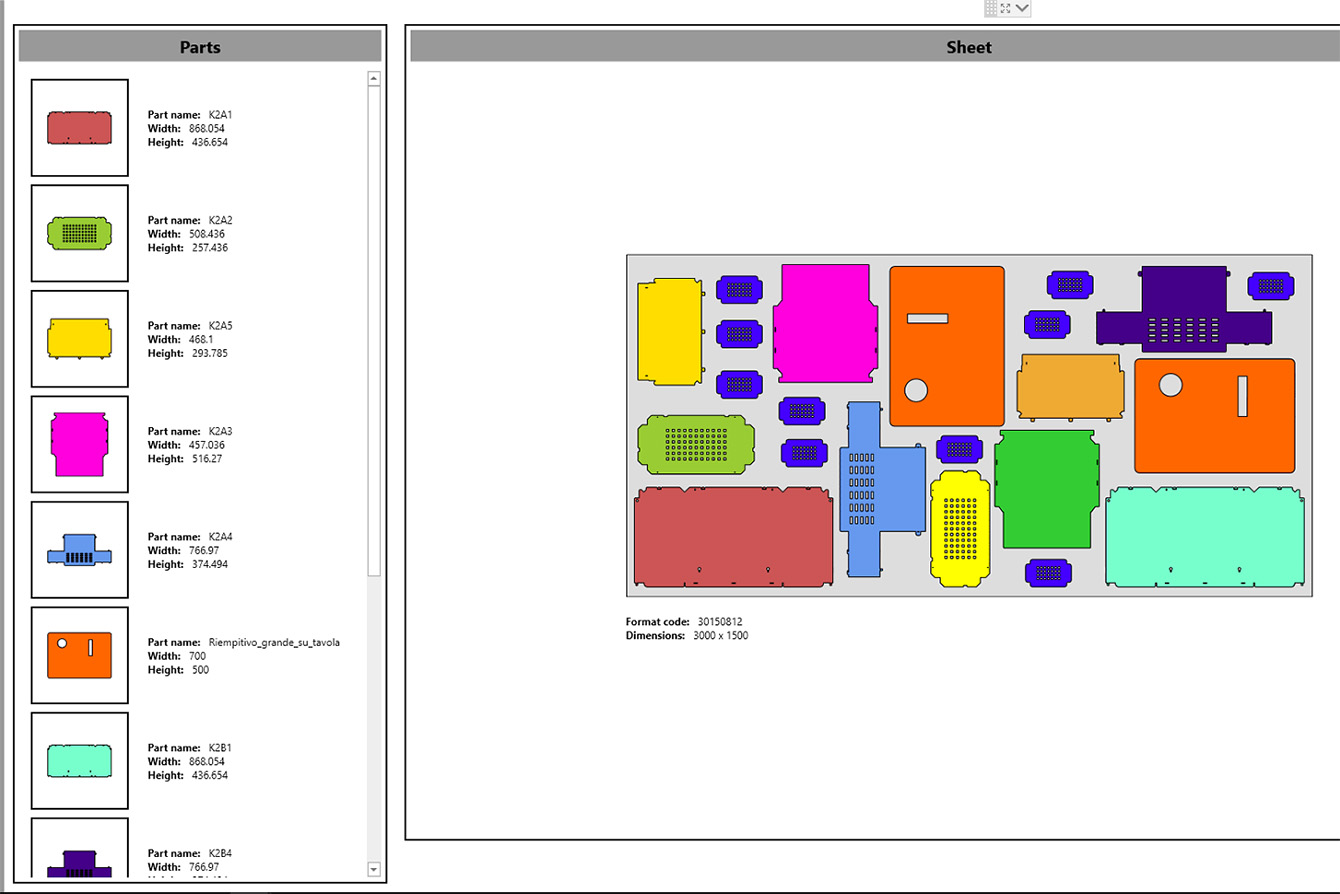

The operator places the sheet metal leftover on the worktable and uses FACE, the Salvagnini human-machine interface, to indicate which is the reference leftover – because there could be more than one on the worktable. The application acquires an image of the leftover, transforms it into a dxf and enters it in the STREAMLASER on machine database as a starting sheet. The operator proceeds to select the parts to be produced, and the application automatically creates the nest and completes the program.

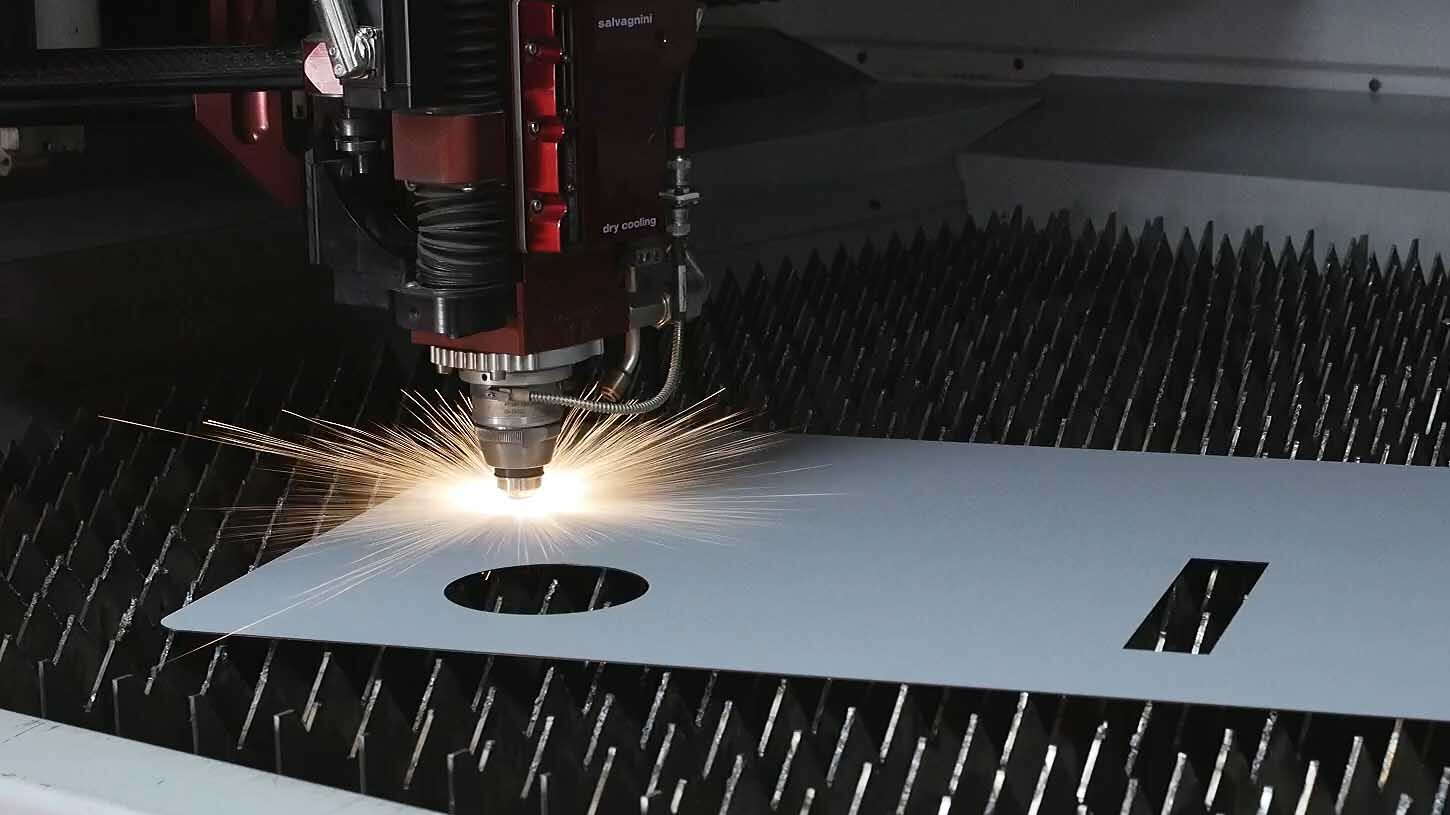

At this point, the actual cutting can start: the laser automatically checks that the leftover is positioned correctly on the worktable and then cuts the defined parts. This option offers great potential in terms of process efficiency.

With SVS it is possible to create nests on more than one leftover: several leftovers can therefore be placed on the worktable if, for example, a number of small leftovers are available - and this possibility enhances the performance of SVS2. Moreover, with a graphics application, it is possible to rapidly call up - visually - the parts belonging to nests that have already been produced and are repeatable with SVS. This is a considerable simplification, above all when we think of the need to urgently produce parts machined only recently which may have been damaged during machining downstream, or for which greater quantities are needed.

SVS1 and SVS2: what are the differences?

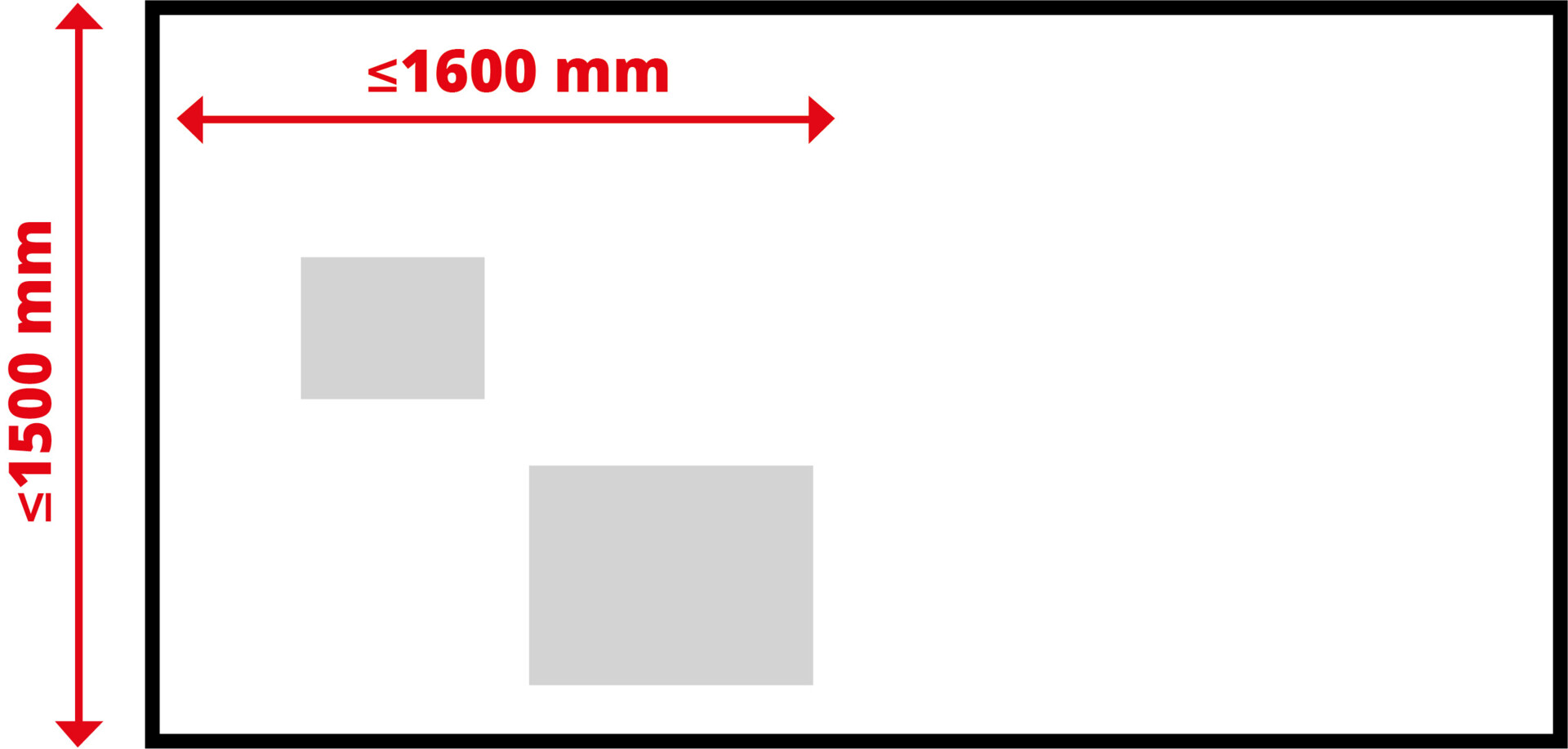

To precisely understand the differences between the two versions of the option, we can look at the pictures. SVS1 has a field of vision, and therefore a working range, of 1600x1500mm. This means that it is possible to position one or more leftovers on the worktable, but these must always be arranged on the left-hand side of the table.

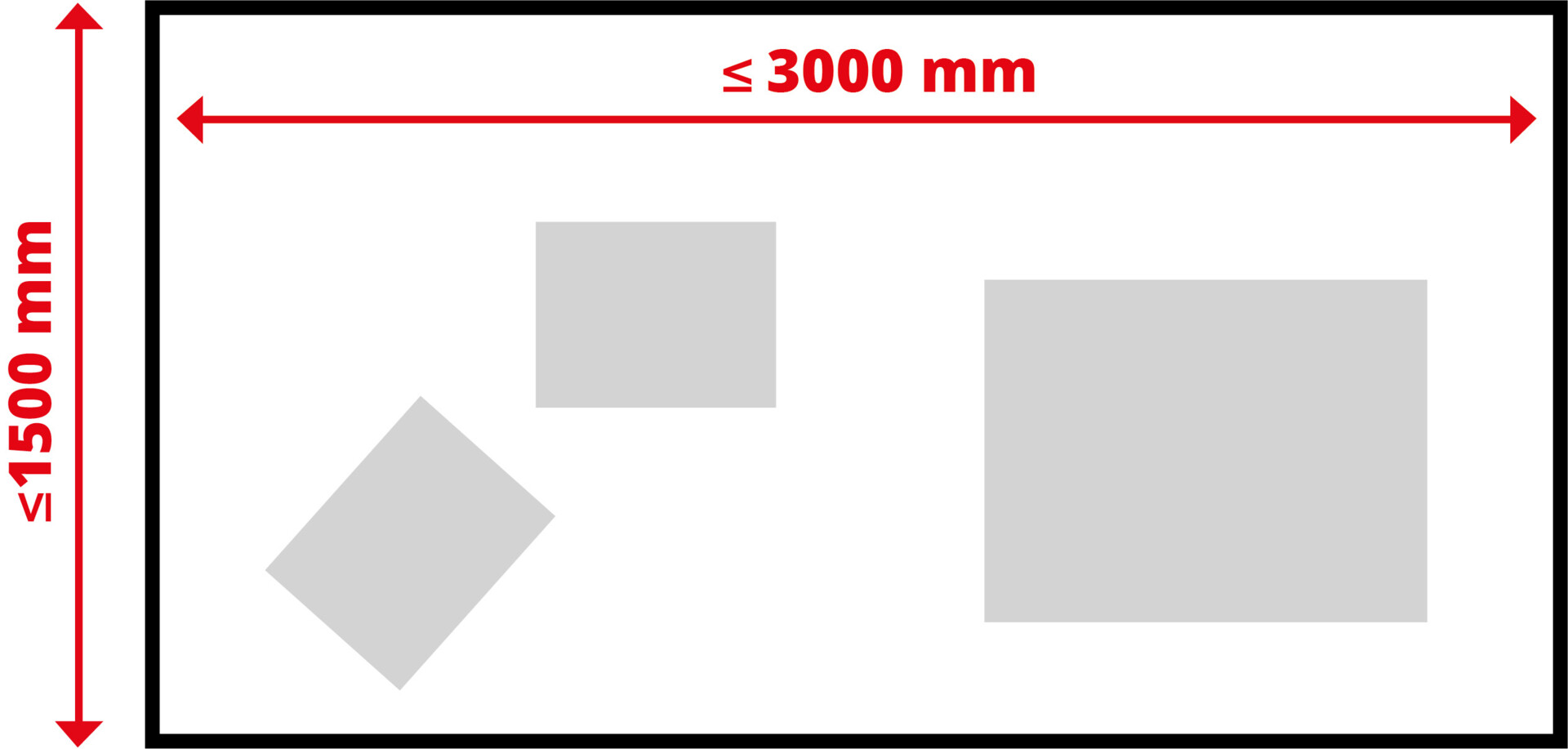

SVS2, on the other hand, has a field of vision of 3000x1500mm and, with its larger working range, offer greater flexibility: both small and large leftovers can be used, positioned in practically any area of the worktable.

In conclusion

So, SVS guarantees a truly wide range of economic and process advantages. And, although the alternative applications available on the market have similar purposes, they are based on different technologies, which greatly limit their effectiveness. Vision systems that support laser cutting are generally applications in augmented reality: they do not transform the images of the leftovers into dxf files to generate a completely automatic nest. In practice, they take a picture of the leftover on the worktable and allow the operator to manually “add” the parts to be produced to the image taken.

The disadvantages here are clear: on the one hand, the operator has to manually enter the parts one by one, without the possibility of creating a nest in automatic filling mode. On the other hand, and more importantly, the process is often completely manual and with no error control: without a dxf, the operator may risk positioning the image of the part to be produced outside the detected outline of the leftover. Additional feature of SVS is also a neural network algorithm that allows sheet alignment as an alternative to a capacitive sensor or AVS. This reduces cycle time by reducing sheet alignment time to 3 seconds, without moving the cutting head or compromising precision.