Case study

Hermes Novak: a choice as simple as the Salvagnini fiber laser

Located in Vienna's 15th district, not far from Schönbrunn Castle, Hermes Novak has been in operation for more than 130 years and is now in its fifth generation. The company is a subcontractor and specializes in laser cutting, for which it has chosen a Salvagnini L3 laser system, as well as in edge banding and welding. We met Wolfgang Novak, owner and managing director of the company.

A choice as simple as the Salvagnini fiber laser

Highlights

- Novak

Stahlbau Novak was founded in 1888 by Wolfgang Novak's great-grandfather. In 1927 he passed the company on to his son, who founded Hermes Novak. "Today we are a traditional subcontractor. We can provide sheet metal components to anyone. For example, we produce various types of housings for the machine tool industry, as well as for the railway industry. Due to our experience in these industries, we have developed specific expertise: our welding competence in the railway sector is certified, as are 7 of our welders. And we also have a welding robot that allows us to make 3D welded parts of about one cubic meter in size," says the owner. - The context

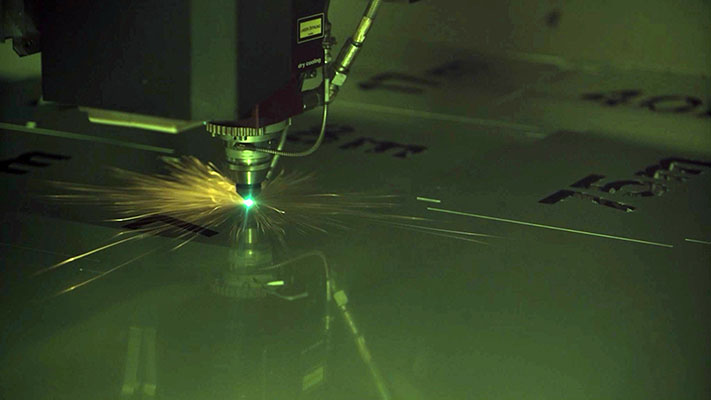

Over the past 30 years, Hermes Novak has gained extensive experience in laser cutting. And has operated a Salvagnini L1 for 17 years with virtually no downtime and infrequent service calls, always fast and effective. - The new L3

"We visited several manufacturers again, but Salvagnini products were our favorite," says Mr. Novak. "Based on our experiences with the L1, we decided not to change supplier and bought an L3 in 2017. Cutting speeds have grown tremendously, and today we're cutting materials we couldn't cut before. The lower consumption compared to a CO2 laser, and the reduced implementation of consumable parts, have led to significant cost savings. And since the fiber laser does not need mirrors, maintenance is much simpler."

Check out the case study

Hear what Wolfgang Novak, owner and Managing Director at Novak, says about the Salvagnini L3 fiber laser.